If you've worked in manufacturing, chances are you've seen a stamping press in action. There's something mesmerizing about the precision, speed, and power these machines bring to the production floor. But whether you're working with a gap frame or a straight-side model, understanding all the components may feel a little overwhelming—it's like piecing together a puzzle made of steel.

Knowing the parts of a press and how they work together gives you the upper hand, whether you're troubleshooting, planning routine maintenance, or even ordering your next press. Understanding the anatomy of the machine can save you time, money, and a whole lot of headaches.

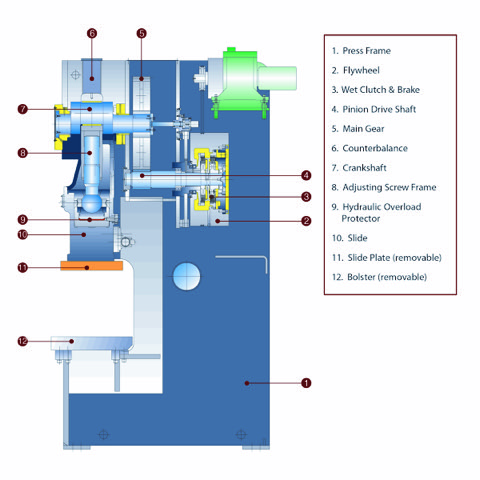

Let's break it all down and take a closer look at the stamping press parts that keep things running smoothly. From the frame (the backbone of the machine) to the slide (the muscle that drives the press) and the automation features that make production faster and more efficient, we'll cover the essential press machine parts. And don't worry—we'll keep it practical and to the point with tips and insights you can use right on the factory floor.

So, whether you're engineering the production line, managing operations, or running the press itself, this article is for you. By the time we're done here, you'll have a solid understanding of the core components that power metal forming processes and keep industries like automotive and aerospace moving.

Table of Contents

A stamping press is a powerhouse that shapes, cuts, and forms metal parts with incredible precision and efficiency. Whether it's an automotive body panel or an intricate electronic component, the magic happens here. But like anything in manufacturing, you can't get great results without the right tools—and in this case, understanding the anatomy of the press is step one.

First things first: all presses are designed with the same basic idea in mind—applying force to a workpiece through a die. But how they accomplish this varies depending on the type of press you're using. There are hydraulic presses and mechanical presses, each with its own strengths. Stamtec specializes in mechanical presses, and for good reason—these machines are built for high-speed production and reliability.

If you're wondering how stamping press parts come together to do such heavy lifting, imagine it like this: the frame is your foundation, the slide (or ram) applies brute force, and the bolster plate holds everything steady. Add in a touch of automation and precise motion control, and you've got a system that transforms raw metal into finished parts with impressive accuracy.

Here's a quick breakdown of what you'll find in a typical press:

The frame is the skeleton that holds everything together. Without a strong, rigid frame, the rest of the components simply wouldn't align or function properly. It's the backbone of the entire operation, and its main job is to withstand the immense forces generated during stamping.

Depending on the application, you'll typically run into two main types of frames:

You've likely seen these compact machines on factory floors. Gap frame presses, also known as C-frame presses (because of their C-shaped structure), are incredibly useful when space is at a premium. These machines are perfect for smaller parts where accessibility is key. Their open design makes it easy to load and unload materials, which is why they're often a go-to for punching, blanking, or light stamping tasks. If you're running tight operations with high output volumes, this might just be the tool for the job.

When handling larger parts or heavier loads, straight side presses are where it's at. These presses feature a fully enclosed, box-like frame that provides superior rigidity and minimizes deflection during stamping. That rigidity translates to consistency—the kind of consistency you need when your parts must meet tight tolerances every single time.

The type of frame you choose depends on your manufacturing needs. For smaller, simpler parts, a gap frame press might do the trick. For bigger parts or those requiring stricter precision, straight side is the way to go.

One final note—frame design doesn't just affect the size or type of parts you're working with. It also plays a role in operator safety, efficiency, and even the durability of the machine itself.

If the frame is the backbone of a stamping press, the slide—or ram—is the muscle. This critical stamping press part does the heavy lifting, applying the force needed to shape, cut, or form metal during the stamping process. It's the moving part of the press that interacts directly with the dies and the material being worked on, delivering precision and power in every stroke.

The slide operates on a straightforward yet essential principle: convert power into controlled force and motion. The better this process works, the better your results will be. In mechanical presses, this force is created via a crankshaft or eccentric gears, which drive the slide up and down in a precise, repeating motion.

Here are a few important features to keep in mind:

Speed is important, but control is just as critical. That's where servo-driven slides come into play. Servo presses take traditional slide motion to the next level. These advanced machines allow operators to fine-tune speed, motion profile, and even dwell time at the bottom of the stroke for maximum flexibility and precision.

If you've ever needed to deep-draw a part or reduce material wrinkling during forming, you know how valuable precise slide control can be. That's why servo-driven technology is quickly becoming a must-have in modern manufacturing facilities.

One of the most critical jobs of the slide is maintaining alignment with the bolster plate and the dies. When the slide tilts even slightly, it can lead to uneven wear on the dies or even damage the parts being produced.

Here are a few things you can do to ensure your equipment's peak performance:

The power transmission system converts rotational energy into the linear force needed to stamp parts. Mechanical presses rely on an efficient system of components to deliver consistent power and speed.

Here's a quick breakdown of these press machine parts:

When you think about the parts of a press, the bolster plate might not be the first thing that comes to mind, but it plays an important role in the stamping process. The bolster plate acts as the mounting surface for the dies—the real tools that shape the metal. It's also the part that absorbs the intense forces generated by the slide during each stroke.

A good bolster plate is strong, flat, and incredibly durable. After all, this surface has to withstand thousands—often millions—of repetitive cycles without warping or losing integrity. But strength isn't the only thing that matters. The design of the bolster plate needs to prioritize easy setup and adaptability for different types of dies.

Let's look at the key features of a bolster plate:

Whether you're forming, blanking, or drawing, a properly maintained bolster plate is key to keeping things running smoothly:

While the frame, slide, and bolster plate handle the heavy lifting, automation ensures everything runs smoothly, safely, and at peak efficiency. Here's a closer look at some of the press machine parts that take your operation to the next level.

The process starts long before the slide comes down. That raw material—whether it's coiled steel, aluminum, or another metal—needs to be prepped, fed, and aligned with precision. Enter feeding & coil handling systems.

There are various solutions, including 3-in-1 Systems, that combine unwinding, straightening, and feeding in one seamless package. These systems ensure the material is perfectly positioned every time, which means fewer errors, higher consistency, and less downtime.

For larger production setups, you might turn to separate feeding equipment or configurable blanking and cut-to-length lines. This kind of flexibility lets manufacturers adapt to different material sizes and jobs.

Die changes used to be a major bottleneck. Switching tooling could eat up hours of valuable production time. But today, quick die change systems make the process faster, safer, and more efficient. These systems also ensure accurate die setup, so you're ready to run your next batch with minimal adjustments.

If you're stamping a single part in a single stroke, it's relatively straightforward. But for more complex parts, you'll need precision material movement between multiple stations. This is where press transfer systems shine. These systems automate the precise handling of parts during multi-step forming processes, ensuring smooth, consistent movement to avoid any disruptions along the way.

Modern presses integrate advanced control systems that let operators monitor everything from cycle speed to tonnage at a glance. Press control and monitoring provide insights in real-time, allowing operators to spot potential issues before they turn into costly downtime. Accurate control also helps fine-tune production runs and generate reliable, repeatable quality for every part.

Pro Tip: When integrating automation, always focus on compatibility. Stamtec's presses and auxiliary equipment are designed to work seamlessly together, giving you a complete system that's greater than the sum of its parts.

If the power transmission system is the engine, then the die space is the workstation. This is where the tooling (or dies) are secured and where the material transforms—blanks become parts, metal sheets become forms, and raw material becomes precision components. The die space is a carefully calibrated area that brings the entire press operation together.

Stamtec's experts are here to help you design a press solution tailored to your production goals. Check out our product lineup today and see how our presses and automation systems can transform your operation!

Our Hydraulic Overload Protection System comes standard on all of our stamping presses. Its primary function is to safeguard the press against exceeding its tonnage capacity. See more press features on the Stamtec YouTube Channel.

Understanding the parts of a press and how they work together can feel complex, but it's also key to optimizing your stamping operations. Below, we've answered some of the most common questions about stamping press components and their roles in manufacturing.

Mechanical presses rely on parts like the flywheel, crankshaft, and gears to convert rotational energy into linear motion, making them ideal for high-speed, high-volume stamping. Hydraulic presses use cylinders and fluid pressure to drive the slide, offering greater control over speed and force, which is beneficial for tasks like deep drawing or variable tonnage applications.

Feeders, transfer systems, and press controls integrate seamlessly with a stamping press to automate material handling, improve precision, and increase output. Feeders ensure consistent positioning of materials, transfer systems move parts between stations, and modern controls provide real-time monitoring and optimization. Together, these systems reduce manual labor while enhancing efficiency and safety.

Proper alignment ensures consistent part quality, protects your dies, and extends press longevity. Key components include the frame and slide, which must align precisely during operation, the bolster plate for maintaining die stability, and gibs (guides) to ensure smooth slide motion. Regular maintenance and proper setup are essential to prevent costly misalignment issues.