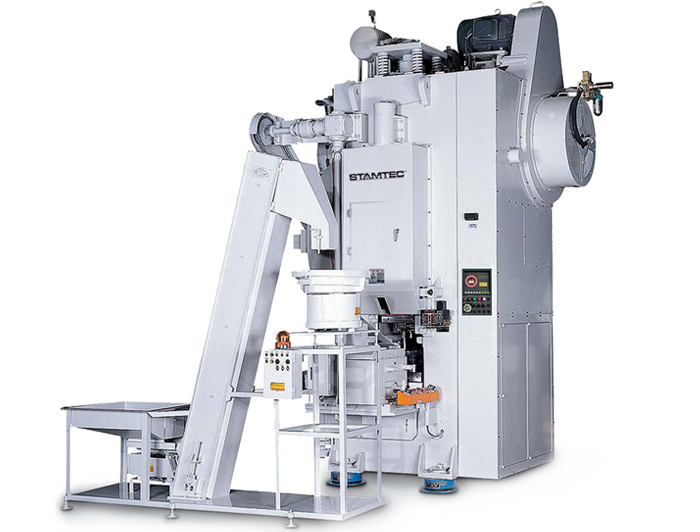

KL2 Series Knuckle Joint Press

KL2 cold forging presses feature a long stroke length above 400 mm and high rating point. It can be applied in drive shaft forging formation with long rod / shaft dimension, especially for the automotive industry requiring production quality and high stamping efficiency.

TONNAGE RANGE: 400 - up to 4,000

Review the specs and features below and then contact us for help for more information on the cold forging machine you need.

Specs

KL2-400

KL2-630

KL2-800

KL2-1000

KL2-1200

KL2-1600

KL2-2000

KL2-Up to 4,000 Tons

Specifications available on request.

Give us a call at 931-393-5050 or complete our request form.

Standard Features

- Slide and tool counterbalance device

- Oil recirculation lubrication device

- Overrun protection device

- Hydraulic overload protection device

- PLC (Mitsubishi FX series)

- Programmable limit switches (8 channel)

- Digital Die height indicator

- Misfeed detection receptacle

- Solenoid Valve

- Safety rail and ladder

- Air ejector (3/8")

- Air receptacle (3/8")

- Maintenance tool kit

- Operation manual and inspection report

- Portable 2-hand push button T-stand

Optional Features

- Flywheel brake

- Light curtain

- Slide knockout device

- Bed knockout device

- Quick die core change arm

- Motorized grease device

- Inverter-duty main motor

- Foot switch

- Tool lightening

- Anti-vibration mount

- Motorized slide adjusting device (hydraulic locking)

- Power receptacle (110V and 220V)

- Programmable Logic control (PLC Mitsubishi Q series)

- Human Machine Interface (HMI- Mitsubishi)

- Anchoring screw and plate

- Quick Die Change

» Upper Die Clamp

» Lower Die Clamp

» Die Lifter

» Die Arm

- Feeding system

Please contact Stamtec for the advantages and components for our KL2 Series steel stamping machines.

STAMTEC IN 60 SECONDS:

STAMTEC IN 60 SECONDS: