Stamtec’s Mechanical Presses (a.k.a. OBG, OBS, OBI, or C-frame) undergo finite element analysis prior to manufacturing to ensure proper design, superior strength and maximum resistance to deflection

The Stamtec OCP one-point gap frame press (a.k.a. OBG, OBS, OBI, or C-frame) is designed for stamping small parts at high single-stroking rates or in continuous mode, using either blanks or coil stock. The OCP metal stamping press provides all the features you expect to find in a world-class press, at a very competitive price, backed by a three-year (calendar-based) warranty without limitation.

TONNAGE RANGE: 27 - 330

DELIVERY TIME: In stock, or with quick delivery

Review the specs and advantages of our OCP Series gap frame press below, and then contact us for assistance in identifying the right mechanical press for your application.

Stamtec stamping press machines can be customized to meet a wider range of SPM, stroke, rating point (BDC), bed and other specifications and dimensions.

| MODEL OCP-35 SPECIFICATIONS | ||||

|---|---|---|---|---|

| Type | S | H | L | |

| Capacity | US Tons | 38 | 38 | 38 |

| Metric Tons | 35 | 35 | 35 | |

| Rated tonnage point | in. | 0.13 | 0.06 | 0.13 |

| mm | 3.2 | 1.6 | 3.2 | |

| Stroke length | in. | 3.15 | 1.77 | 4.33 |

| mm | 80 | 45 | 110 | |

| Speed | SPM | 70 ~ 135 | 90 ~ 180 | 50 ~ 95 |

| Die height | in. | 9.84 | 9.84 | 9.25 |

| mm | 250 | 250 | 235 | |

| Slide adjustment | in. | 2.17 | 2.17 | 2.17 |

| mm | 55 | 55 | 55 | |

| Bolster area (L-R X F-B) | in. | 30.71 x 13.40 | 30.71 x 13.40 | 30.71 x 13.40 |

| mm | 780 x 340 | 780 x 340 | 780 x 340 | |

| Bolster thickness | in. | 2.76 | 3.34 | 2.76 |

| mm | 70 | 85 | 70 | |

| Slide area (L-R X F-B) | in. | 14.96 x 12.60 | 14.96 x 12.60 | 14.96 x 12.60 |

| mm | 380 x 320 | 380 x 320 | 380 x 320 | |

| Main motor (VS) | Hp | 5 | 5 | 5 |

| Slide adjustment motor | Hp | Manual | Manual | Manual |

| DIE CUSHION DEVICE | ||||

| Type | S | H | L | |

| Capacity | US Tons | - | - | 2.6 |

| Pad area (LR x FB) | in. | - | - | 11.81 x 9.06 |

| mm | - | - | 300 x 230 | |

| Stroke | in. | - | - | 1.97 |

| mm | - | - | 50 | |

| MACHINE DIMENSIONS | ||||

| Type | S | H | L | |

| Width (LR) | in. | 36.61 | 36.61 | 36.61 |

| mm | 930 | 930 | 930 | |

| Depth (FB) | in. | 47.24 | 47.24 | 47.24 |

| mm | 1200 | 1200 | 1200 | |

| Height (H) | Inch | 82.68 | 82.68 | 82.68 |

| mm | 2100 | 2100 | 2100 | |

| MODEL OCP-45 SPECIFICATIONS | ||||

|---|---|---|---|---|

| Type | S | H | V | |

| Capacity | US Tons | 49.5 | ||

| Metric Tons | 45 | |||

| Rated tonnage point | in. | 0.13 | 0.09 | 0.13 |

| mm | 3.2 | 2.3 | 3.2 | |

| Stroke length | in. | 2.76 | 1.97 | 4.33 |

| mm | 70 | 50 | 100 | |

| Variable speed | SPM | 65 ~ 130 | 85 ~ 175 | 50 ~ 95 |

| Die height | in. | 11.42 | 11.81 | 10.63 |

| mm | 290 | 300 | 270 | |

| Max upper die weight | lbs. | 661.39 | ||

| kg | 300 | |||

| Slide adjustment | in. | 2.36 | ||

| mm | 60 | |||

| Bolster area (L-R X F-B) | in. | 33.47 x 17.32 | ||

| mm | 850 x 350 | |||

| Bolster thickness | in. | 3.54 | ||

| mm | 90 | |||

| Slide area (L-R X F-B) | in. | 16.93 x 13.78 | ||

| mm | 430 x 350 | |||

| Main motor (VS) | Hp x P | 5 x 4 | ||

| Working height | in. | 31.5 | ||

| mm | 800 | |||

| Slide adjustment motor | kW x P | Manual | ||

| MODEL OCP-60 SPECIFICATIONS | ||||

|---|---|---|---|---|

| Type | S | H | V | |

| Capacity | US Tons | 66 | ||

| Metric Tons | 60 | |||

| Rated tonnage point | in. | 0.16 | 0.09 | 0.16 |

| mm | 4 | 2.3 | 4 | |

| Stroke length | in. | 3.15 | 1.97 | 5.11 |

| mm | 80 | 45 | 110 | |

| Variable speed | SPM | 60 ~ 120 | 80 ~ 165 | 40 ~ 85 |

| Die height | in. | 12.8 | 13.39 | 11.81 |

| mm | 325 | 340 | 300 | |

| Max upper die weight | lbs. | 661.39 | ||

| kg | 300 | |||

| Slide adjustment | in. | 2.76 | ||

| mm | 70 | |||

| Bolster area (L-R X F-B) | in. | 35.43 x 20.47 | ||

| mm | 900 x 520 | |||

| Bolster thickness | in. | 3.54 | ||

| mm | 90 | |||

| Slide area (L-R X F-B) | in. | 19.69 x 15.75 | ||

| mm | 500 x 400 | |||

| Main motor (VS) | Hp x P | 7.5 x 4 | ||

| Working height | in. | 31.5 | ||

| mm | 800 | |||

| Slide adjustment motor | kW x P | 0.4 x 4 | ||

| MODEL OCP-80 SPECIFICATIONS | ||||

|---|---|---|---|---|

| Type | S | H | V | |

| Capacity | US Tons | 88 | ||

| Metric Tons | 80 | |||

| Rated tonnage point | in. | 0.2 | 0.13 | 0.2 |

| mm | 5 | 3.2 | 5 | |

| Stroke length | in. | 3.84 | 2.36 | 5.91 |

| mm | 100 | 60 | 150 | |

| Variable speed | SPM | 50 ~ 100 | 65 ~ 140 | 40 ~ 75 |

| Die height | in. | 13.98 | 14.76 | 12.99 |

| mm | 355 | 375 | 300 | |

| Max upper die weight | lbs. | 760.60 | ||

| kg | 345 | |||

| Slide adjustment | in. | 3.15 | ||

| mm | 80 | |||

| Bolster area (L-R X F-B) | in. | 39.37 x 23.62 | ||

| mm | 1000 x 600 | |||

| Bolster thickness | in. | 3.94 | ||

| mm | 100 | |||

| Slide area (L-R X F-B) | in. | 22.05 x 18.11 | ||

| mm | 560 x 460 | |||

| Main motor (VS) | Hp x P | 10 x 4 | ||

| Working height | in. | 32.68 | ||

| mm | 830 | |||

| Slide adjustment motor | kW x P | 0.4 x 4 | ||

| MODEL OCP-110 SPECIFICATIONS | ||||

|---|---|---|---|---|

| Type | S | H | V | |

| Capacity | US Tons | 121.25 | ||

| Metric Tons | 110 | |||

| Rated tonnage point | in. | 0.2 | 0.13 | 0.2 |

| mm | 5 | 3.2 | 5 | |

| Stroke length | in. | 4.33 | 2.76 | 7.09 |

| mm | 110 | 70 | 180 | |

| Variable speed | SPM | 45 ~ 90 | 60 ~ 130 | 30 ~ 65 |

| Die height | in. | 15.16 | 15.95 | 13.78 |

| mm | 385 | 405 | 350 | |

| Max upper die weight | lbs. | 992.08 | ||

| kg | 450 | |||

| Slide adjustment | in. | 3.54 | ||

| mm | 90 | |||

| Bolster area (L-R X F-B) | in. | 45.28 x 26.77 | ||

| mm | 1150 x 680 | |||

| Bolster thickness | in. | 4.72 | ||

| mm | 120 | |||

| Slide area (L-R X F-B) | in. | 25.59 x 20.47 | ||

| mm | 650 x 520 | |||

| Main motor (VS) | Hp x P | 15 x 4 | ||

| Working height | in. | 33.27 | ||

| mm | 845 | |||

| Slide adjustment motor | kW x P | 0.4 x 4 | ||

| MODEL OCP-160 SPECIFICATIONS | ||||

|---|---|---|---|---|

| Type | S | H | V | |

| Capacity | US Tons | 176.37 | ||

| Metric Tons | 160 | |||

| Rated tonnage point | in. | 0.24 | 0.16 | 0.24 |

| mm | 6 | 4 | 6 | |

| Stroke length | in. | 5.12 | 3.15 | 7.87 |

| mm | 130 | 80 | 200 | |

| Variable speed | SPM | 35 ~ 70 | 50 ~ 100 | 20 ~ 50 |

| Die height | in. | 17.13 | 18.11 | 15.75 |

| mm | 435 | 460 | 400 | |

| Max upper die weight | lbs. | 1190.50 | ||

| kg | 540 | |||

| Slide adjustment | in. | 3.94 | ||

| mm | 100 | |||

| Bolster area (L-R X F-B) | in. | 49.21 x 29.92 | ||

| mm | 1250 x 760 | |||

| Bolster thickness | in. | 5.91 | ||

| mm | 150 | |||

| Slide area (L-R X F-B) | in. | 27.56 x 22.84 | ||

| mm | 700 x 580 | |||

| Main motor (VS) | Hp x P | 20 x 4 | ||

| Working height | in. | 36.02 | ||

| mm | 915 | |||

| Slide adjustment motor | kW x P | 0.75 x 4 | ||

| MODEL OCP-200 SPECIFICATIONS | ||||

|---|---|---|---|---|

| Type | S | H | V | |

| Capacity | US Tons | 220.46 | ||

| Metric Tons | 200 | |||

| Rated tonnage point | in. | 0.24 | 0.16 | 0.24 |

| mm | 6 | 4 | 6 | |

| Stroke length | in. | 5.91 | 3.94 | 7.87 |

| mm | 150 | 100 | 200 | |

| Variable speed | SPM | 35 ~ 70 | 45 ~ 95 | 20 ~ 50 |

| Die height | in. | 18.70 | 19.69 | 17.72 |

| mm | 475 | 500 | 450 | |

| Max upper die weight | lbs. | 1763.70 | ||

| kg | 800 | |||

| Slide adjustment | in. | 4.33 | ||

| mm | 110 | |||

| Bolster area (L-R X F-B) | in. | 55.12 x 32.28 | ||

| mm | 1400 x 820 | |||

| Bolster thickness | in. | 6.30 | ||

| mm | 160 | |||

| Slide area (L-R X F-B) | in. | 33.47 x 25.59 | ||

| mm | 850 x 650 | |||

| Main motor (VS) | Hp x P | 20 x 4 | ||

| Working height | in. | 40.16 | ||

| mm | 1020 | |||

| Slide adjustment motor | kW x P | 0.75 x 4 | ||

| MODEL OCP-260 SPECIFICATIONS | ||||

|---|---|---|---|---|

| Type | S | H | V | |

| Capacity | US Tons | 286.60 | ||

| Metric Tons | 260 | |||

| Rated tonnage point | in. | 0.24 | 0.16 | 0.24 |

| mm | 6 | 4 | 6 | |

| Stroke length | in. | 7.09 | 3.94 | 9.84 |

| mm | 180 | 100 | 250 | |

| Variable speed | SPM | 30 ~ 60 | 35 ~ 75 | 20 ~ 40 |

| Die height | in. | 19.10 | 20.67 | 17.72 |

| mm | 485 | 525 | 450 | |

| Max upper die weight | lbs. | 1763.70 | ||

| kg | 800 | |||

| Slide adjustment | in. | 4.72 | ||

| mm | 120 | |||

| Bolster area (L-R X F-B) | in. | 59.06 x 33.07 | ||

| mm | 1550 x 840 | |||

| Bolster thickness | in. | 7.09 | ||

| mm | 120 | |||

| Slide area (L-R X F-B) | in. | 36.22 x 27.56 | ||

| mm | 920 x 700 | |||

| Main motor (VS) | Hp x P | 25 x 4 | ||

| Working height | in. | 44.10 | ||

| mm | 1120 | |||

| Slide adjustment motor | kW x P | 1.5 x 4 | ||

| MODEL OCP-300 SPECIFICATIONS | ||||

|---|---|---|---|---|

| Type | S | H | V | |

| Capacity | US Tons | 330.69 | ||

| Metric Tons | 300 | |||

| Rated tonnage point | in. | 0.24 | 0.16 | 0.24 |

| mm | 6 | 4 | 6 | |

| Stroke length | in. | 7.09 | 3.94 | 9.84 |

| mm | 180 | 100 | 250 | |

| Variable speed | SPM | 30 ~ 50 | 35 ~ 75 | 20 ~ 40 |

| Die height | in. | 19.10 | 20.67 | 17.72 |

| mm | 485 | 525 | 450 | |

| Max upper die weight | lbs. | 1763.70 | ||

| kg | 800 | |||

| Slide adjustment | in. | 4.72 | ||

| mm | 120 | |||

| Bolster area (L-R X F-B) | in. | 61.02 x 33.07 | ||

| mm | 1550 x 840 | |||

| Bolster thickness | in. | 7.09 | ||

| mm | 120 | |||

| Slide area (L-R X F-B) | in. | 36.22 x 27.56 | ||

| mm | 920 x 700 | |||

| Main motor (VS) | Hp x P | 30 x 4 | ||

| Working height | in. | 44.10 | ||

| mm | 1120 | |||

| Slide adjustment motor | kW x P | 1.5 x 4 | ||

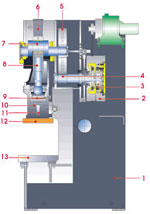

Heavy, one-piece welded steel frame is designed to resist deflection, providing more accurate stampings and longer die life.

Heavy, one-piece welded steel frame is designed to resist deflection, providing more accurate stampings and longer die life.

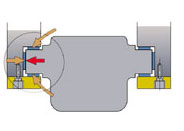

Fast-response hydraulic overload relieves the pressure of a tonnage overload in milliseconds, stopping the press immediately and protecting press and dies from damage.

Extra-long gibs provide excellent control of slide alignment and accuracy throughout the entire stroke.

Slide comes equipped with a removable, steel, T-slotted die-mounting plate for easy modification, repair or replacement.

Wet clutch and brake provide long life, very low maintenance, and high performance even at high single-stroking rates.

At no additional cost, our press control comes with features that are often optional on standard press controls:

• Six programmable limit switches

• Four programmable die protection inputs

• LCD display screen for status and fault messages

• LED display for crank angle and spm

Our OCP Series 1-point gap frame presses come standard with:

Options on our OCP Series 1-point gap frame presses include: