KP Series Knuckle-Joint 1-Point Cold Forging

Knuckle-Joint 1-Point Cold Forging Presses

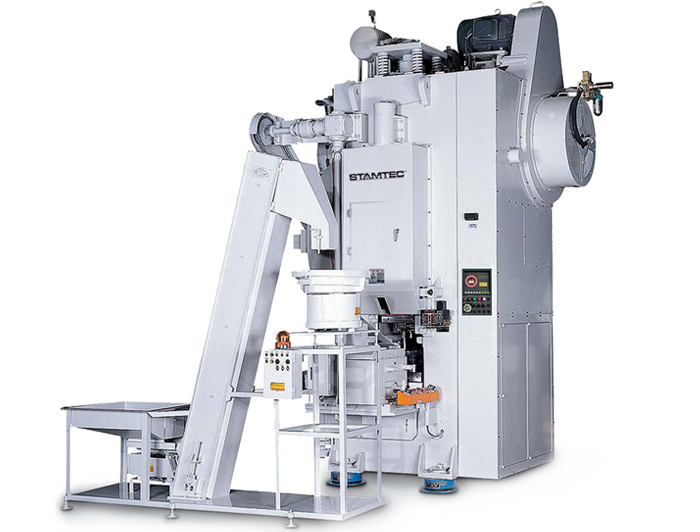

Stamtec Cold Forge Technology

Stamtec cold forging press technology provides particular advantages for producing steel components, improving strength and consistency. Benefits include near net shape forming, improved mechanical characteristics, superior plasticity, higher surface quality, and increased productivity.

K Knuckle Joint Series

The KP Series cold-forging press is just one of a group of Stamtec knuckle-joint presses designed to improve and expand part production capabilities. Our knuckle-joint mechanism can alter the motion velocity of the press slide to a slow speed as it approaches the bottom dead-end center point, providing important benefits not only for cold forging but also for extrusion, coining, upsetting, sizing and heading.

TONNAGE RANGE: 250 - up to 4,000

Review the specs, advantages and features below and then contact us for more information on the cold forging press you need.

Specs

KP-250

KP-400

KP-650

KP-850

KP-1000

KP-1200

KP-2000

KP-Up to 4,000 Tons

Specifications available on request.

Give us a call at 931-393-5050 or complete our request form.

Press Advantages

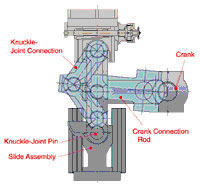

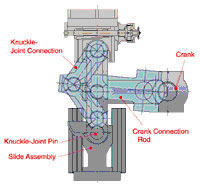

The slide on our KP Series cold forging machine is connected to the crankshaft by a linked knuckle mechanism that adapts the revolution of the crankshaft to the up-and-down motion of the slide, achieving a mechanical advantage that supplies very high tonnage near the bottom of the stroke.

Standard Features

- Near net-shape forming

- Better mechanical characteristics

- Superior plasticity

- Good surface quality

- Higher productivity

Optional Features

- Bottom Scrap tank (Front side)

- VS Motor (APC optional)

- Photo electronic safety guard

- Anti Vibration Mount

- Foundation Plate and Anchor Bolts

- Safety Block and Plug

- Die Room Light

- Hydraulic Slide Knock-out Device

- Hydraulic Die Cushion

Please contact Stamtec for information concerning components for our KP Series steel stamping machines.

STAMTEC IN 60 SECONDS:

STAMTEC IN 60 SECONDS:  The slide on our KP Series cold forging machine is connected to the crankshaft by a linked knuckle mechanism that adapts the revolution of the crankshaft to the up-and-down motion of the slide, achieving a mechanical advantage that supplies very high tonnage near the bottom of the stroke.

The slide on our KP Series cold forging machine is connected to the crankshaft by a linked knuckle mechanism that adapts the revolution of the crankshaft to the up-and-down motion of the slide, achieving a mechanical advantage that supplies very high tonnage near the bottom of the stroke.