Stamtec’s Mechanical Presses (a.k.a. OBG, OBS, OBI, or C-frame) undergo finite element analysis prior to manufacturing to ensure proper design, superior strength and maximum resistance to deflection

The Stamtec PL2 Series double crank press features our Link Motion Drive Technology, designed for deeper or more complex forming, at high single-stroking rates or in continuous mode, using either blanks or coil stock.

Stamtec’s link motion drive technology decreases slide velocity by up to 40 percent during the working portion of the stroke so the material flows more effectively while the non-working portion of the stroke increases by an offsetting amount to maintain high production rates.

Click here to view our recent white paper - A Guide to Link Motion Mechanical Presses

Stamtec PL2 Series Link Motion Press specifications can be customized to individual customer requirements (see below for PL2 specification examples). To design your custom PL2 Series mechanical press, contact us today.

Stamtec mechanical presses can be customized to meet a wider range of SPM, stroke, rating point (BDC), bed and other specifications and dimensions.

| MODEL PL2-440 SPECIFICATIONS | ||

|---|---|---|

| Capacity | US Tons | 440 |

| Metric Tons | 400 | |

| Rated tonnage point | in. | 0.51 |

| mm | 13 | |

| Stroke length | in. | 6.00 or 12.00 |

| mm | 152 or 305 | |

| Speed | SPM | 20 ~ 40 |

| Die height | in. | 37.79 |

| mm | 960 | |

| Slide adjustment (powered) | in. | 10 |

| mm | 254 | |

| Slide area (L-R x F-B) - Option 1 | in. | 86.61 x 51.18 |

| mm | 2200 x 1300 | |

| Slide area (L-R x F-B) - Option 2 | in. | 95.98 x 55.11 |

| mm | 2438 x 1400 | |

| Bolster area (L-R x F-B) - Option 1 | in. | 86.61 x 51.18 |

| mm | 2200 x 1300 | |

| Bolster area (L-R x F-B) - Option 2 | in. | 95.98 x 55.11 |

| mm | 2438 x 1400 | |

| Side frame opening (window) (F-B x H) | in. | 43.30 x 25.59 |

| mm | 1100 x 650 | |

| Bolster thickness | in. | 7.87 |

| mm | 200 | |

| Working height | in. | 49.21 |

| mm | 1250 | |

| Overall dimensions (approx.) - (L-R-F-B) | in. | 180 x 100 |

| mm | 4570 x 4580 | |

| Overall height | in. | 247 |

| mm | 6291 | |

| Counter balance capacity | lbs. | 10008 |

| Kgs | 4540 | |

| Weight (approx.) | lbs. | TBD |

| Kgs | TBD | |

| Main motor horsepower | H.P. | 75 |

| Slide adjustment horsepower | H.P. | 4 |

| Standard voltage on stock machines is 480. | ||

| Standard Paint Color - RAL-7035, Light Grey | ||

| Parallelism: Slide to Bolster - .001" per foot or less | ||

| Deflection: .0015" per foot or less R to L & F to B with 2/3 of the bed area symmetrically loaded. | ||

| MODEL PL2-550 SPECIFICATIONS | ||

|---|---|---|

| Capacity | US Tons | 550 |

| Metric Tons | 500 | |

| Rated tonnage point | in. | 0.51 |

| mm | 13 | |

| Stroke length | in. | 6.00 or 12.00 |

| mm | 152 or 305 | |

| Speed | SPM | 20 ~ 40 |

| Die height | in. | 37.79 |

| mm | 960 | |

| Slide adjustment (powered) | in. | 10 |

| mm | 254 | |

| Slide area (L-R x F-B) - Option 1 | in. | 86.61 x 51.18 |

| mm | 2200 x 1300 | |

| Slide area (L-R x F-B) - Option 2 | in. | 95.98 x 55.11 |

| mm | 2438 x 1400 | |

| Bolster area (L-R x F-B) - Option 1 | in. | 86.61 x 51.18 |

| mm | 2200 x 1300 | |

| Bolster area (L-R x F-B) - Option 2 | in. | 95.98 x 55.11 |

| mm | 2438 x 1400 | |

| Side frame opening (window) (F-B x H) | in. | 43.30 x 25.59 |

| mm | 1100 x 650 | |

| Bolster thickness | in. | 7.87 |

| mm | 200 | |

| Working height | in. | 49.21 |

| mm | 1250 | |

| Overall dimensions (approx.) - (L-R-F-B) | in. | 180 x 100 |

| mm | 4570 x 4580 | |

| Overall height | in. | 247 |

| mm | 6291 | |

| Counter balance capacity | lbs. | 10008 |

| Kgs | 4540 | |

| Weight (approx.) | lbs. | TBD |

| Kgs | TBD | |

| Main motor horsepower | H.P. | 75 |

| Slide adjustment horsepower | H.P. | 4 |

| Standard voltage on stock machines is 480. | ||

| Standard Paint Color - RAL-7035, Light Grey | ||

| Parallelism: Slide to Bolster - .001" per foot or less | ||

| Deflection: .0015" per foot or less R to L & F to B with 2/3 of the bed area symmetrically loaded. | ||

| MODEL PL2-660 SPECIFICATIONS | ||

|---|---|---|

| Capacity | US Tons | 660 |

| Metric Tons | 600 | |

| Rated tonnage point | in. | 0.52 |

| mm | 13 | |

| Stroke length | in. | 9.84 |

| mm | 250 | |

| Speed (* includes dynamic balancing | SPM | * 30 ~ 70 |

| of the eccentric shaft) | ||

| Die height | in. | 29.52 |

| mm | 750 | |

| Slide adjustment (powered) | in. | 3.93 |

| mm | 100 | |

| Slide area (L-R x F-B) | in. | 98.43 x 55.12 |

| mm | 2500 x 1400 | |

| Bolster area (L-R x F-B) | in. | 98.43 x 55.12 |

| mm | 2500 x 1400 | |

| Side frame opening (window) (F-B x H) | in. | 50 x 25.6 |

| mm | 1270 x 650 | |

| Bolster thickness | in. | 9.85 |

| mm | 250 | |

| Working height | in. | 35.43 |

| mm | 900 | |

| Overall dimensions (approx.) - (L-R-F-B) | in. | 165.74 x 145.66 |

| mm | 4210 x 3700 | |

| Overall height | in. | 240 |

| mm | 6100 | |

| Counter balance capacity | lbs. | 11000 |

| Kgs | 5000 | |

| Weight (approx.) | lbs. | 291000 |

| Kgs | 131995.38 | |

| Main motor horsepower | H.P. | 175 |

| Slide adjustment horsepower | H.P. | 10 |

| Parallelism: Slide to Bolster - .001" per foot or less | 0.001 | |

| Deflection measured R to L and F to B with 2/3 of the bed area | 0.001 | |

| symmetrically loaded. | ||

| Snap Through Rating | 0.25 | |

| MODEL PL2-880 SPECIFICATIONS | ||

|---|---|---|

| Capacity | US Tons | 880 |

| Metric Tons | 800 | |

| Rated tonnage point | in. | 0.52 |

| mm | 13 | |

| Stroke length | in. | 12.01 |

| mm | 305 | |

| Speed | SPM | 25 ~ 40 |

| Die height | in. | 31.5 |

| mm | 800 | |

| Slide adjustment (powered) | in. | 5.91 |

| mm | 150 | |

| Slide area (L-R x F-B) - Option 1 | in. | 168 x 63 |

| mm | 4270 x 1600 | |

| Slide area (L-R x F-B) - Option 2 | in. | 144 x 63 |

| mm | 3660 x 1600 | |

| Bolster area (L-R x F-B) - Option 1 | in. | 168 x 63 |

| mm | 4270 x 1600 | |

| Bolster area (L-R x F-B) - Option 2 | in. | 144 x 63 |

| mm | 3660 x 1600 | |

| Side frame opening (window) (F-B x H) | in. | 51.19 x 31.50 |

| mm | 1300 x 800 | |

| Bolster thickness | in. | 11.82 |

| mm | 300 | |

| Working height | in. | 27.96 |

| mm | 710 | |

| Counter balance capacity | lbs. | 15400 |

| Kgs | 6985 | |

| Main motor horsepower | H.P. | 150 x 4 |

| Slide adjustment horsepower | H.P. | 15 x 6 |

| Standard Paint Color - RAL-7035, Light Grey | ||

| Parallelism: Slide to Bolster - .001" per foot or less | ||

| Deflection: .0015" per foot or less R to L & F to B with 2/3 of the bed area symmetrically loaded. | ||

Hydraulic Overload Protection System (H.O.L.P.)

Hydraulic Overload Protection System (H.O.L.P.)

Stamtec’s unique dual-valve automatic hydraulic overload protection system protects each side of the double crank press individually from overloads.

Air Counterbalance System

The weight of the slide, connection housing assemblies, upper die, etc., is offset by an adjustable air counterbalance system.

Lubrication System

All anti-friction bearings, sleeve bushings and gibs are lubricated by a sequencing self-monitoring re-circulating oil lubrication system which is interlocked with the mechanical press emergency stop circuit.

Digital Die Height Indicator

A die height indicator is mounted on the front of the slide for operator convenience in making die height adjustments.

Die Safety Block

Two (2) Die safety blocks with holders are included. The safety blocks are supplied with a plug and receptacle interlocked into the press controls.

Press Pneumatic System

The pneumatic system includes the necessary regulator valves, gauges, lubricators, and air filters for each double crank press.

Knockout Bars (Optional)

As a standard feature, the slide is arranged to accept knockout bars.

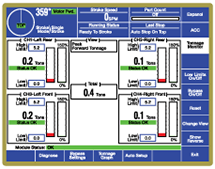

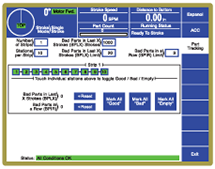

Every Stamtec mechanical press features advanced, user-friendly automation controls with fully programmable on-screen displays for easy set-up, start-up, operation and diagnostics.

Our standard presses come equipped with OmniLink 5100-APC Press Automation Controls.