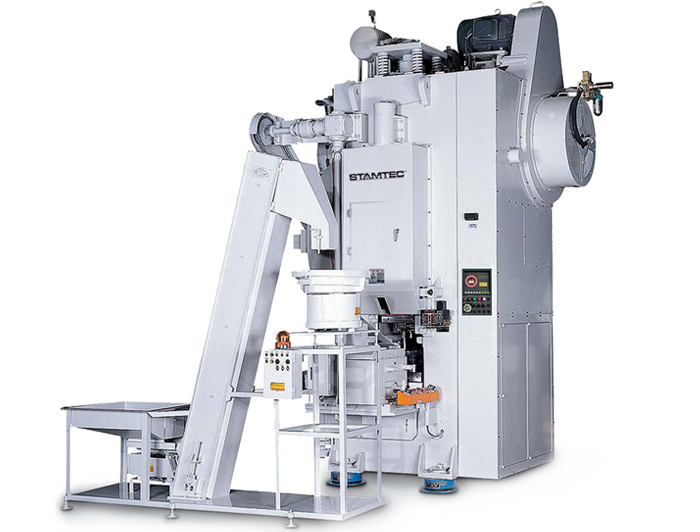

KW1 Series Cold and Semi-Hot Forging Presses

Stamtec’s KW1 Series Cold and Semi-Hot Forging Knuckle-Joint Presses, especially when coupled with feeder and transfer equipment, is effective and efficient in forging and drawing thick sheet material.

The wet clutch on these cold and semi-hot forging presses delivers high torque and performance at relatively low air pressure. Friction linings run in an enclosed oil bath, providing a very long lived clutch and brake with efficient heat dissipation, low vibration, minimal noise, reduced lining wear, and lower air consumption, even at high single-stroke rates of production.

TONNAGE RANGE: 300 - up to 4,000

Read the specs and press advantages below and then contact us for help identifying the knuckle-joint press your operation requires.

Specs

KW1-300

KW1-400

KW1-500

KW1-650

KW1-800

KW1-1000

KW1-Up to 4,000 Tons

Specifications available on request.

Give us a call at 931-393-5050 or complete our request form.

Press Advantages

The KW knuckle-joint drive system on our KW1 Series cold and semi-hot forge press provides the following benefits:

- The knuckle-joint mechanism provides for high precision and repeatability, with a long dwell time at bottom dead center.

- Lower snap through as a result lower slide velocity through the bottom portion of the stroke, resulting in lower part shear reverse tonnage, vibration, punch penetration, and noise.

- LCD display screen for status and fault messages.

- Maximized straight line vertical force at BDC allowing for difficult forming and coining.

- Plunger-guiding (KW2 only), in conjunction with full-length nickel bronze 8-point gibbing and slide wear plates, offers maximum control, accuracy, ease of adjustment, and enables production of tight-tolerance parts. The plungers are guided by heavy plunger housings with bronze bushings. Side thrust is partially absorbed by the plunger guide housings and crown, helping to produce only vertical force through the slide and connections for greatest accuracy. In addition, uneven wear of the gibs and slide wear plates is minimized.

Please contact Stamtec for information on components and standard and optional features.

STAMTEC IN 60 SECONDS:

STAMTEC IN 60 SECONDS: