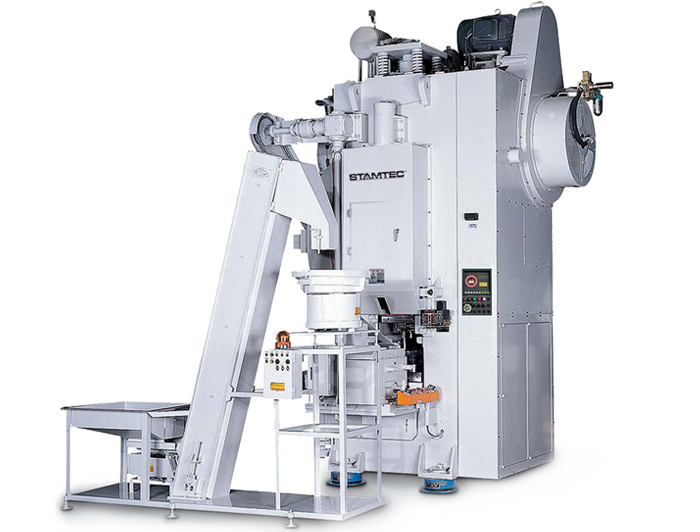

Mechanical Forging Press

For many components, cold or hot forging offers crucial production efficiencies & benefits like strength, integrity & material savings.

REQUEST A CUSTOM QUOTE

For many components, cold or hot forging offers crucial production efficiencies & benefits like strength, integrity & material savings.

REQUEST A CUSTOM QUOTEWarm-hot forging presses are ideal for producing parts made from material with flow characteristics that can only be achieved by warming it first (e.g., automotive parts, hand tools, gears, engine parts and net shape forming).

Click on a forging press below to learn more, and then contact us for assistance in selecting the press that meets your needs.

Choosing the right hot forging press is crucial for optimizing your manufacturing process. Stamtec's WF1 Series Warm-Hot Forging Presses not only enhance the strength of your components but also streamline production. With a tonnage range of 400 to 4,000, these presses are versatile enough to meet various industrial needs—from automotive components to medical equipment. Stamtec's hot forging machine technology is designed for high performance, providing value that surpasses the investment.

Understanding the specifications and benefits of Stamtec's KW1 Series Cold and Semi-Hot Forging Presses can greatly aid in your purchasing decision. These presses are built to last, offering:

While both series offer exceptional durability and performance, the WF1 Series focuses more on high-value-added parts in warm-hot forging, particularly beneficial for industries like automotive components, medical equipment and household appliances. The KW1 Series excels in cold and semi-hot forging processes, making it ideal for work that requires high torque and efficient material handling.

Choosing between Stamtec's WF1 Series Warm-Hot Forging Press and KW1 Series Cold and Semi-Hot Forging Presses depends on your specific needs. Both options, coupled with Stamtec’s longstanding reputation for quality, make for a solid investment in your operation's future.

Our hot forging press machines are versatile and beneficial for a wide array of industries. The high-value components produced by a hot forging press are particularly advantageous for sectors requiring superior material strength and precision.

Selecting the right machine for your specific application can make a significant difference in production efficiency and product quality. Hot forging presses are ideal for:

By choosing Stamtec's warm-hot forging machines, you can be assured of a high-quality, reliable solution that aligns with your production goals.

We are a leading manufacturer of forge press machines. Investing in a hot forging press machine offers a range of benefits that can translate into both immediate and long-term gains for your business. Stamtec's machines provide:

By incorporating a Stamtec hot forging press machine into your operations, you're not just purchasing equipment; you're investing in a long-term solution that contributes positively to your bottom line.

We've compiled a list of frequently asked questions to help you make informed decisions about our hot and warm forging machines.

Selecting the right hot forging machine for your business involves considering several critical specifications. Here are some key factors to keep in mind:

By carefully reviewing these specifications, you can more confidently choose a Stamtec hot forging press machine that aligns with your operational needs and production goals.

When it comes to reliability and performance, Stamtec's hot forging machines set industry benchmarks. Known for their durability and consistent product quality, these machines feature components like wet clutches and enclosed oil baths that contribute to long equipment life. Additionally, our hot forging presses have been designed to minimize vibration and noise. Stamtec's commitment to quality is backed by more than 70 years of experience in the field.

We provide an extensive library of resources to assist our clients, such as specialized white papers, informative videos comprehensive catalogs and more, all geared to optimize the performance of your hot forging press machine and additional Stamtec machinery For any inquiries, feel free to reach out and we'll gladly assist you.

In a marketplace that demands both quality and efficiency, making the right machinery investment is pivotal. Stamtec’s hot forging press machines offer the robust performance, reliability and versatility needed to elevate your production capabilities. Don’t miss out on an opportunity to maximize your return on investment and stay ahead of the competition.

Contact us today to schedule a personalized consultation or request a quote and discover how Stamtec can tailor a hot forging press solution to meet your specific operational needs.

Both of our warm-hot forging press machine series provide important advantages for your operation:

Massive bed is built to a standard of no more than .0015-inch deflection per foot of bed length, both left to right and front to back, with a full-capacity load symmetrically distributed over two thirds of the bed area.

Design provides superior compressive strength, deflection, torsion and vibration resistance.

The frame on these metal presses is connected with four full-length steel tie rods that are hydraulically pre-stressed to 150 percent of press capacity and welded together to form a single, unitized weldment.