Coil-handling and feeding systems, quick die change systems, & more to meet your specific needs

Stamtec brand advanced coil handling equipment can revolutionize your metal stamping and forming operations, delivering speed, precision, and quality like never before.

From decoiling to feeding, our machinery streamlines your workflow and maximizes productivity. Our flexible systems overcome any challenge regardless of material thickness or floor space limitations.

Stamtec presses can also be CUSTOMIZED with your choice of feeding & coil handling systems from:

With Stamtec, you can confidently tackle even the most demanding stamping and metal forming requirements. Contact us today for more information on our press feed and coil handling equipment, including:

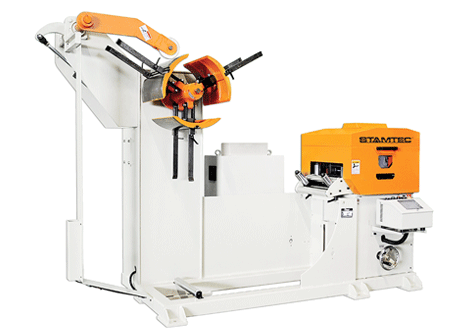

Stamtec 3-IN-1 Servo Feeder, Straightener, and Uncoiler are accurate, versatile, and designed to handle various material widths and thicknesses.

What sets them apart is their compact size, taking up as much as 50% less floor space compared to traditional systems with separate uncoilers, straighteners, and feeders.

In addition to their space-saving feature, our 3-IN-1 systems reduce waste and offer enhanced capabilities. With an ergonomic design, they ensure efficient operation, meeting the specific needs of your press room.

Stamtec 2-IN-1 Compact Straightener and Uncoiler provides optimum straightening and excellent value.

Noteworthy for their space-saving, modular design they can handle various material widths and thicknesses, increasing production capabilities for applications ranging from thin- to heavy-duty stamping.

Stamtec offers a modular design, rugged construction and high quality components to ensure exceptional performance and dependable feeds.

Stamtec designs, engineers, and integrates complete PRODUCTION LINES, capable of processing a wide range of material types, thicknesses, yield strengths, widths, and weights.

Custom line solutions are built with equipment designed specific to your needs and requirements.