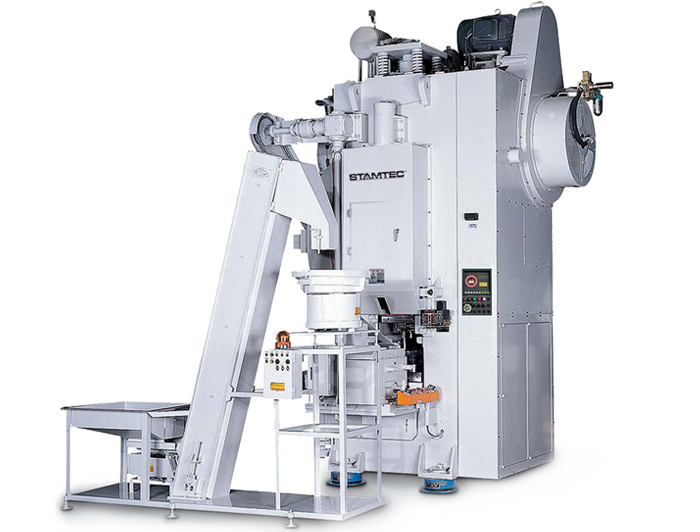

KT Series Knuckle-Joint Cold Forging Press

Knuckle-Joint, Auto-Transferring Presses

Stamtec Cold Forge Technology

Stamtec cold forging press technology provides particular advantages for producing steel components, improving strength and consistency. Near net shape forming, improved mechanical characteristics, superior plasticity, higher surface quality, and increased productivity are just some of the benefits of cold forging presses.

K Knuckle Joint Series

Stamtec KT Series Forging Presses are specially designed for cold forging and are ideal for near net-shape forming. The cold forge technology forms steel components without cutting metal fibers, giving the product a more consistent and durable strength

TONNAGE RANGE: 400 - up to 4,000

Review the specs, advantages and features below and then contact us for more information on the cold forging press you need.

Specs

KT-400

KT-650

KT-800

KT-1000

KT-Up to 4,000 Tons

Specifications available on request.

Give us a call at 931-393-5050 or complete our request form.

Press Advantages

The slide on our KT Series knuckle-joint press is connected to the crankshaft by a linked knuckle mechanism that modifies the motion of the slide, achieving a mechanical advantage and dwell that supplies very high tonnage near the bottom of the stroke.

Standard Features

- Air counterbalance system

- Motorized slide adjustment with hydraulic locking unit

- Centralized re-circulating lubrication device

- Overrun protection device

- Load monitor

- OmniLink 5100-MPC press control system

- 4-digit die height indicator

- Misfeed detection circuit

- Air Ejector (3/8”)

- Air receptacle (3/8”)

- Maintenance tool kit

- Operating manual and inspection report (English)

- Portable 2-hand pushbutton t-stand

Optional Features

- Flywheel brake device

- Bed knockout device

- Motorized grease lubrication system

- Additional electronic rotary cam switches

- Variable frequency drive

- Foot switchLights for tooling area

- 1-phase 100V and 220V power receptacle

- Anti-vibration mounts

- Anchor bolts and plates

- Quick die change system

» Upper die clamp

» Lower die clamp

» Die lifter

» Extension arm

- Auto feeding system

- Remote monitoring & control system

Please contact Stamtec for information concerning components for our KT Series stamping press.

STAMTEC IN 60 SECONDS:

STAMTEC IN 60 SECONDS: