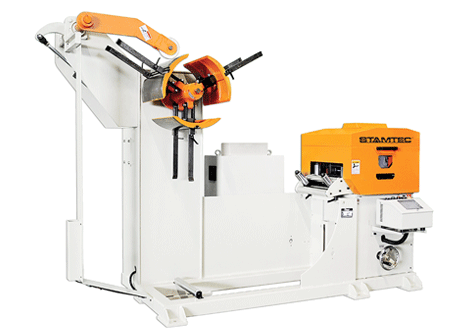

Coil-handling and feeding systems, quick die change systems, & more to meet your specific needs

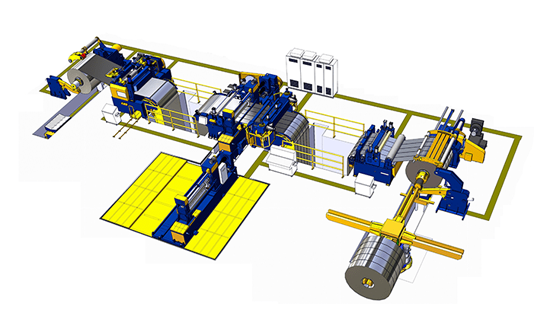

Step into the future with Stamtec's cutting-edge cut-to-length machinery, where advanced material handling meets innovation. These machines are a pivotal part of a more extensive system designed to enhance efficiency and automate the mundane.

With features focused on improving material flow and minimizing manual intervention, Stamtec's technology ensures that every aspect of the production line is optimized for speed and accuracy. Integrating such advanced systems demonstrates a commitment to keeping pace with industry advancements and setting new standards for what's possible in material handling and production processes.

Stamtec stands at the forefront of innovation in metal stamping and forming operations, offering an unparalleled selection of cut-to-length machine solutions. Cut-to-length machines are the backbone of efficient, precision-based manufacturing processes. With a focus on intelligent design and exceptional performance, Stamtec's cut-to-length machines ensure materials are processed accurately and with minimal waste, aligning with the industry's demand for reliability and quality.

Stamtec delivers equipment that meets operational needs, making them a go-to source for businesses seeking to enhance their production capabilities.

Stamtec's cut-to-length line and cut-to-length machinery represent the pinnacle of metal processing technology, combining state-of-the-art design with unparalleled manufacturing expertise. These machines transform the way metal is processed, from coil to finished product. Here are the key features and benefits that distinguish Stamtec in the competitive landscape:

Cut-to-length technology reveals a landscape where precision meets innovation. Stamtec's cut-to-length machines embody this fusion, offering unparalleled accuracy in material processing. This technology redefines efficiency and reliability in metal stamping and forming operations. With features designed to handle various material types and thicknesses, these machines ensure that every cut is precise every time.

Integrating advanced control systems further enhances accuracy, making Stamtec's machinery an essential asset for industries demanding high standards. Understanding the intricacies of this technology is the first step toward recognizing its potential to revolutionize your production processes, ensuring every piece is cut to exact specifications and at a continuous speed.

Stamtec's cut-to-length line machinery is indispensable across various industries, each with unique demands and challenges. These machines offer unparalleled precision and efficiency, from the precise fabrication of automotive components to the sturdy materials needed in construction and the intricate parts required by the electronics sector.

By catering to such a broad and diverse range of applications, Stamtec's cut-to-length machinery demonstrates the universal applicability and necessity of precise material processing. It highlights the company's role as a foundational pillar in the global manufacturing ecosystem. Stamtec's commitment to innovation ensures that industries worldwide can meet the evolving needs of their markets.

Stamtec's cut-to-length machines are more than just cutting tools; they represent a leap forward in material handling and automation. These machines incorporate advanced technologies to streamline operations, enhance efficiency and minimize manual intervention. By improving material flow, Stamtec helps businesses maintain the highest standards of precision and quality.

Whether dealing with separated coil handling and press feeding equipment, or delicate sheets, these machines ensure every piece is handled with care and accuracy. Explore how Stamtec's advanced material handling solutions can revolutionize your all press feeding production lines, paving the way for a more efficient and cost-effective manufacturing process.

Navigating the intricacies of cut-to-length line machinery can often lead to many questions, especially for businesses seeking to integrate these advanced systems into their operations. To assist you in making an informed decision, we've compiled a list of Frequently Asked Questions about Stamtec's cut-to-length machines. We address common inquiries, clarify technical aspects and provide deeper insights into how our machinery can meet your specific manufacturing needs.

Stamtec's machines are versatile enough to handle various materials, from metal sheets to composite panels, ensuring precision cuts regardless of the material type.

By automating the cutting process, these machines minimize manual handling, reduce waste and ensure consistent quality, significantly improving overall production efficiency.

Yes, Stamtec works closely with clients to tailor machines to specific production requirements, ensuring the best fit for your unique needs.

Stamtec provides comprehensive after-sales support, including maintenance, replacement parts and technical assistance, to keep your machine running smoothly.

Find out how Stamtec can tailor a solution to your production needs. Our team is ready to assess your requirements, provide expert recommendations and outline the potential returns on your investment. Whether aiming to enhance productivity, reduce waste or achieve unparalleled accuracy, a Stamtec cut-to-length machine can be the cornerstone of your production's success. Don't wait to transform your operations; reach out today and see how Stamtec's commitment to excellence can work for you.