A Mechanical Press plays a vital role in various industries, driving the production of diverse parts through precise movements controlled by sophisticated press drives. Understanding the intricate dynamics of these drives is crucial for optimizing performance and achieving desired production outcomes.

Table Of Contents

At Stamtec, we recognize the multifaceted requirements of stamping operations, which is why we offer a comprehensive range of mechanical press machine drive options tailored to suit different applications and stamping needs.

One of the most important is the drive that controls the movement of the die and directly affects the type of part produced. Selecting the right drive depends on several application requirements, including:

Our drive train offerings include:

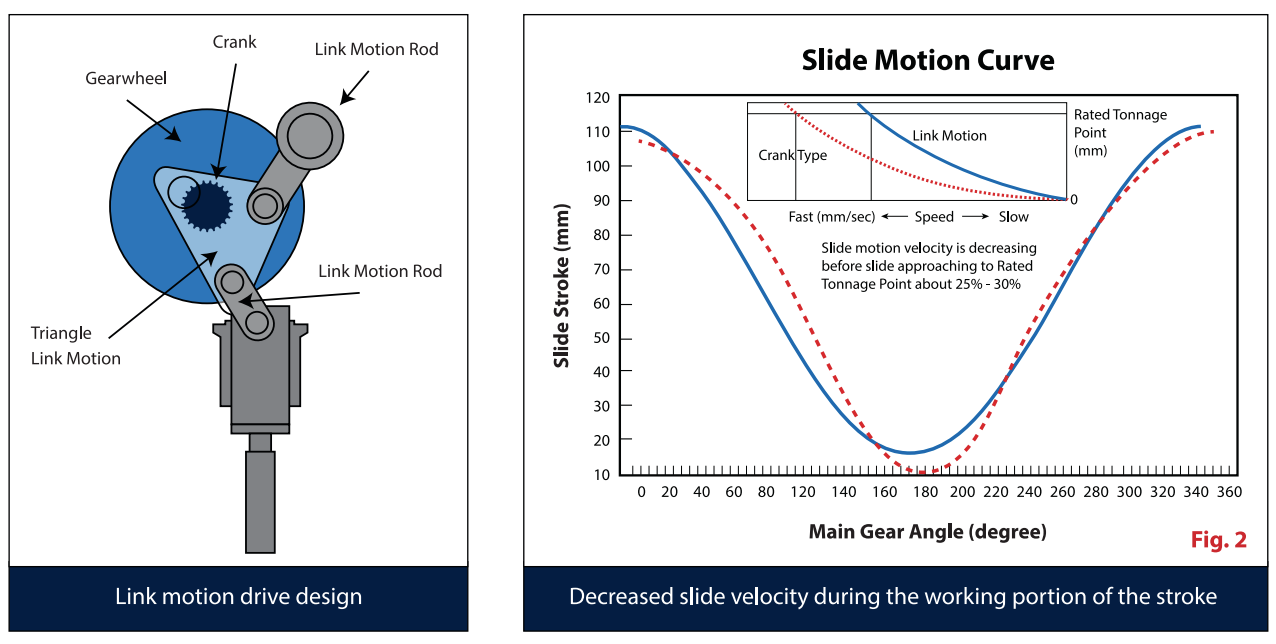

In addition to traditional press drive options, Stamtec offers cutting-edge link motion drives designed to elevate mechanical press capabilities. These drives are engineered to tackle deeper or more complex forming tasks while increasing productivity by 20% to 40%.

With a link motion press drive, the slide velocity decreases by up to 40% during the working portion of the stroke (Fig, 2)

Slide velocity in the non-working portion of the stroke increases by an offsetting amount to maintain high production rates. The results are better quality parts produced at higher production speeds. In addition, the slower speed of the working stroke reduces die impact, punch penetration, snap-through, noise and vibration, increasing machine and die life.

There are four main types of link motion drives for our mechanical presses:

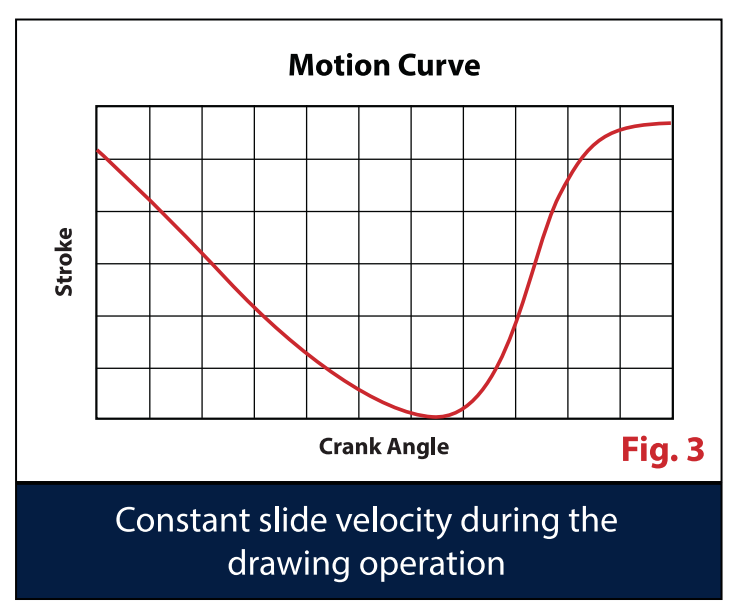

Draw Link motion drives are usually used for deep drawing options. The metal is stretched and formed without tearing due to the reduced slide velocity through the working portion of the press stroke. The reduction improves part quality and decreases side wall thinning by providing a more constant slide velocity during the drawing operation. (Fig 3)

Although ideal for deep drawing operations, draw link motion limits performance in other operations, like blanking, coining, forming, and progress die, because of the small amount of time the slide spends near the bottom of the stroke.

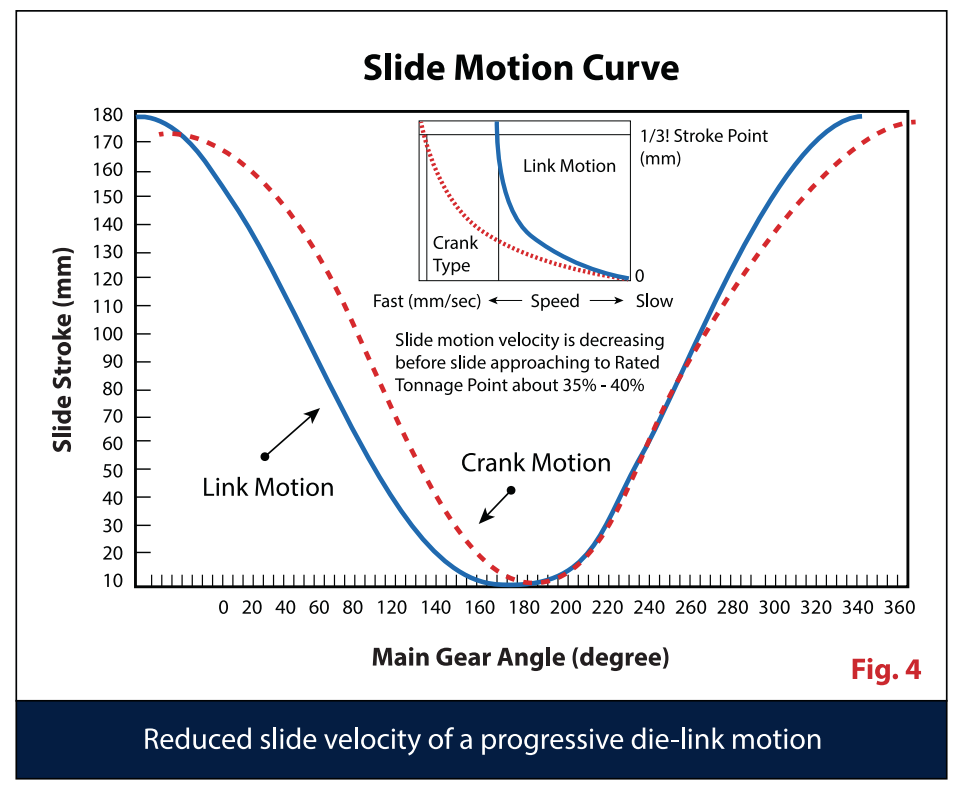

Also known as drag or slider, Progressive Die Drives are specifically designed to improve the performance of progressive die operation performance. They reduce the slide velocity of the press stroke by 20% to 40%. Applied pressure increases metal plasticity and forming capabilities – the longer the pressure is applied, the more these features are enhanced.

Metal plasticity provides benefits like:

The lost time created by the slide velocity reduction during the lower portion of the press stroke is regained by increased velocity through the upper portion of the stroke. (Fig. 4) Progressive die motion drives do not sacrifice strokes per minute and can increase operating speeds by at least 25%.

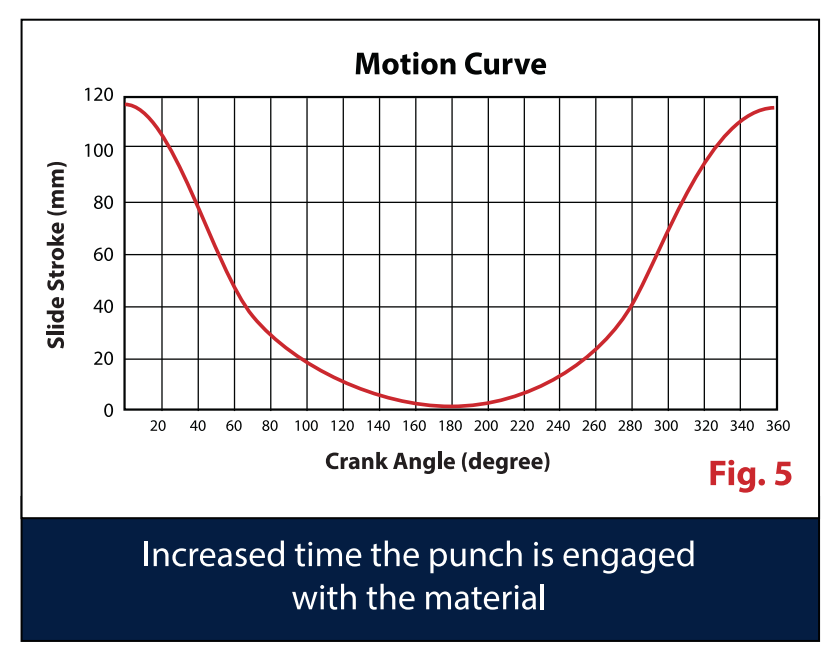

Vertical link drives are common in coil-fed forming operations where the press applies pressure. The length of time the punch is engaged with the material can more than double with this type of drive. (Fig. 5)

Like progressive die drives, vertical link drives improve press performance by operating at a significantly lower slide velocity. The slower slide velocity increases material flow and enhances the production of net-shape parts, eliminating the need for secondary machining operations.

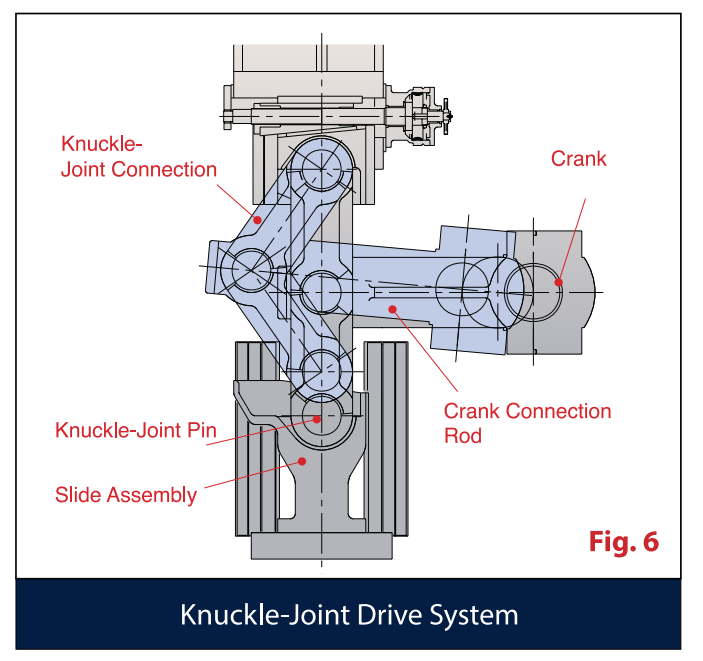

Knuckle-joint drives provide a modified slide motion specifically developed for near-net-shape forming where a very high degree of metal flow is needed. This drive slows down the slide during the working portion of the stroke and produces a significant dwell at the bottom of the stroke.

Knuckle-joint benefits include:

Designed for thicker materials and net-shape blanking and coining, knuckle-joint drives also provide capabilities for wider stamping applications.

Stamtec offers a variety of press models with available link motion drives, including:

Stamtec is committed to providing the perfect drive option to maximize your mechanical press performance. Contact us today to explore how our drives can empower your stamping operations and streamline your production processes.