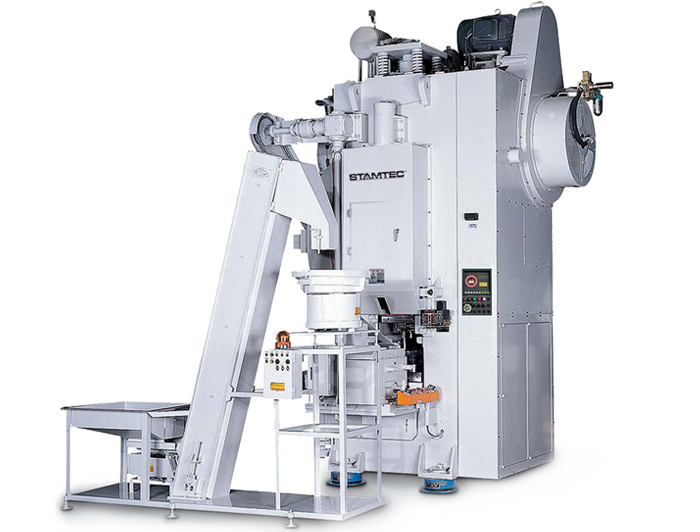

WF1 Series Warm-Hot Forging Press

Providing our customers with the ability to produce high-value-added parts on Warm-Hot Forging Presses. The WF1 Series presses are optimized for warm-hot forging operations requiring power and consistency. For more general specs, visit our Warm-Hot Forging Presses overview page.

The warm-hot forging process can be widely applied to products and industries including automotive vehicle components, tools, household appliances, medical equipment, motors and national defense. This process provides the strength of cold forming, yet shortens the forming process and adds more value to the finished product. For alternate forging needs, consider our KW1 Series Cold & Semi-Hot Forging Presses for precision under various conditions.

TONNAGE RANGE: 400 - up to 4,000

Read the specs and press advantages below to learn more, and then contact us for help identifying the warm-hot forge press your application demands.

Specs

WF1-400

WF1-600 & 600G

WF1-800 & 800G

WF1-1,000 & 1,000G

WF1-1,600 & 1,600G

WF1-Up to 4,000 Tons

Specifications available on request.

Give us a call at 931-393-5050 or complete our request form.

Press Advantages

- Ideal for sheet materials in cold forging, drawing, fine blanking, near-net-shaping (net shape), and press forging.

- Suitable for press forging of light compound materials such as magnesium, aluminum, or sheet steel, and high-tension steels.

- Super rigid, low-detection steel frame

- Link-motion drive combined with a knuckle-joint transmission system creates a unique slide motion curve.

- Adaptable to Fine Blanking for knives, hardware, and auto parts.

Standard Features

- Dry-type clutch and brake

- Slide and tool counterbalance device

- Motorized slide adjusting device (with hydraulic locking)

- Centralized re-circulation lubrication system

- Overrun protection device

- Main motor reversing circuit

- Load monitoring detector

- Electronic rotary cam switch

- Crank angle indicator (clock type)

- Electromagnetic counter

- Digital die height indicator (unit:0.1mm)

- Misfeed detection receptacle

- Programmable logic controller

- Thermal sensor

- Portable run station on t-stand

- Floor-type cabinet

- Safety ladder and rail

- Air ejector

- Air receptacle

- OmniLink 5100-APC controls (Stamtec presses can be CUSTOMIZED with your choice of press controls)

Optional Features

- Flywheel brake

- Footswitch (with declaration letter)

- Stick release device

- Motorized grease lubrication device (for bed knock-out device)

- Extended module for electronic rotary cam switch (16 channels per unit)

- Front safety door

- Slide knock-out device

- Bed knock-out device

- Anti vibration mounts

- Safety die block and plug

- Automation equipment

- Quick die change system

- Intelligent forming productivity management aystem

Please contact Stamtec for information concerning components for our warm-hot metal stamping machines .

STAMTEC IN 60 SECONDS:

STAMTEC IN 60 SECONDS: