Coil-handling and feeding systems, quick die change systems, & more to meet your specific needs

Stamtec's separated coil handling and press feeding equipment provides a modular approach to increase production capabilities and streamline your operation. Our systems provide the speed, quality and precision to exceed your most demanding stamping requirements.

Review the separate pieces below and then contact us for the shears, servo feeders and coil handling equipment designed to overcome the most difficult challenges you face.

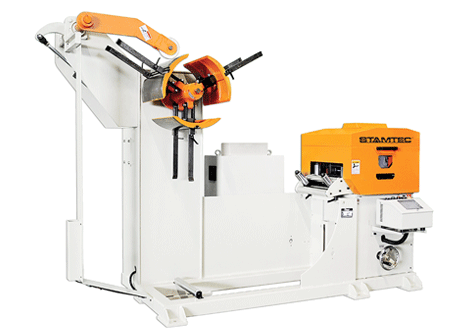

Stamtec Uncoilers

Stamtec UNCOILERS are designed for exceptional performance and durability. Uncoilers can be matched with straighteners and feeders to provide a complete system with a wide range of material width and coil weight capabilities.

Coil width: 11.81 ~ 78.74 in. (300 ~ 2000 mm)

Coil weight: 1.10 ~ 33.07 US Tons (1 ~ 30 Metric Tons)

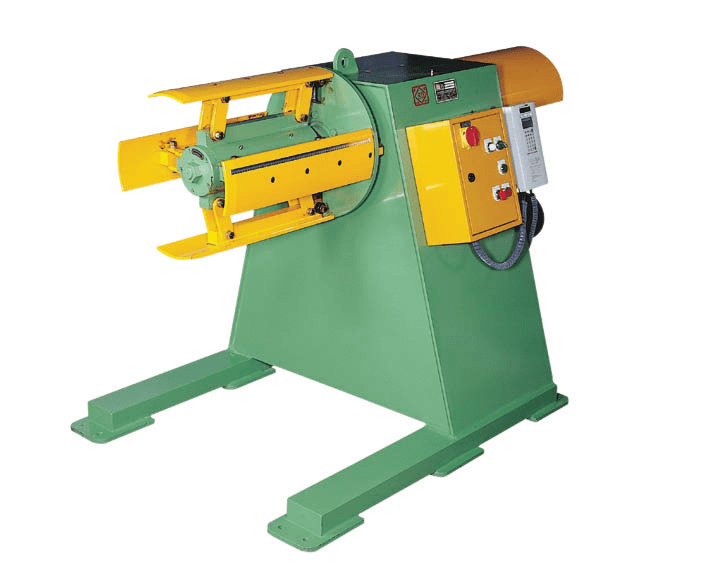

Stamtec Coil Straighteners

When floor space is at a premium, Stamtec STRAIGHTENERS are your solution. Equipped with entrance and exit rolls and adjustable brakes, our coil straighteners offer increased flexibility, adjustable speeds and easy loading.

Coil width: 7.87 ~ 62.99 in. (200 ~ 1600 mm)

Coil thickness: 0.004 ~ 0.126 in. (0.1 ~ 3.2 mm)

Straightening rolls: 7 ~ 22 pcs

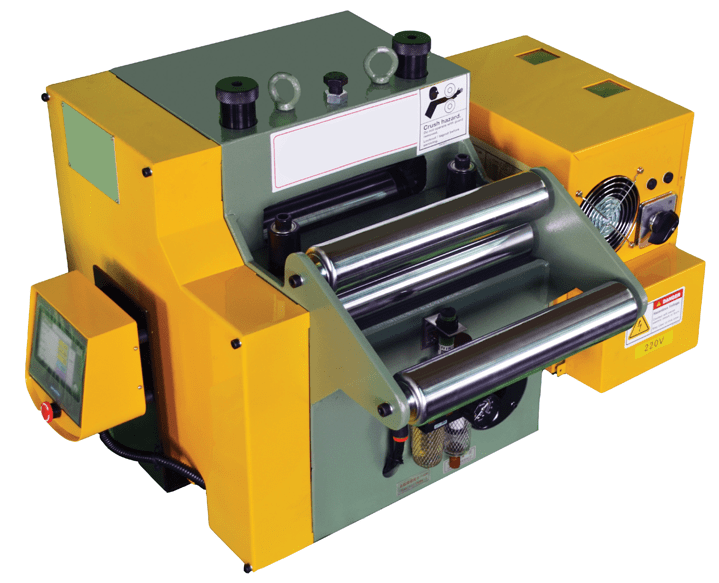

Stamtec Servo Feeders

Stamtec SERVO FEEDERS offer a modular design, rugged construction and high quality components to ensure exceptional performance and dependable feeds.

Coil width: 7.87 ~ 62.99 in. (200 ~ 1600 mm)

Coil thickness: 0.004 ~ 0.315 in. (0.1 ~ 8.0 mm)

Stamtec Press Shears

Stamtec SHEARS are a dependable option for cutting continuous coil into blanks. Our shears can be integrated into a new or existing blanking or transfer press system.

Coil thickness: 7.87 ~ 62.99 in. (200 ~ 1600 mm)

Coil width: 0.01 ~ 0.24 in. (0.3 ~ 6.0 mm)