Coil-handling and feeding systems, quick die change systems, & more to meet your specific needs

Stamtec Servo Presses use the BEST in servo motor technology and controls to enable a virtually unlimited number of stroke and slide movement profiles, while supplying full working energy even at slow speeds / dwells.

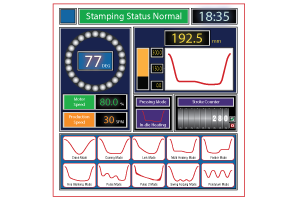

User-Friendly Interface

Servo press controls specifically designed for the servo press achieve a wide variety of stroke lengths and slide movement profiles, while supplying full working energy capacity even at low speeds.

This allows users to perform a wide variety of jobs in one press (drawing, re-strike, warm forming, etc.) and easily adapt to automation and feed applications.

Diversified Curves

In addition, servo press controls enable end-users to request unique profiles, while customized motion curves allow up to 20 various segments in a cycle curve, defined by segment position, speed, and pause duration parameters.

Contact us today for the servo press controls that can make a difference in your stamping operation.