Field service & replacement parts where & when you need them

Field service & replacement parts where & when you need them

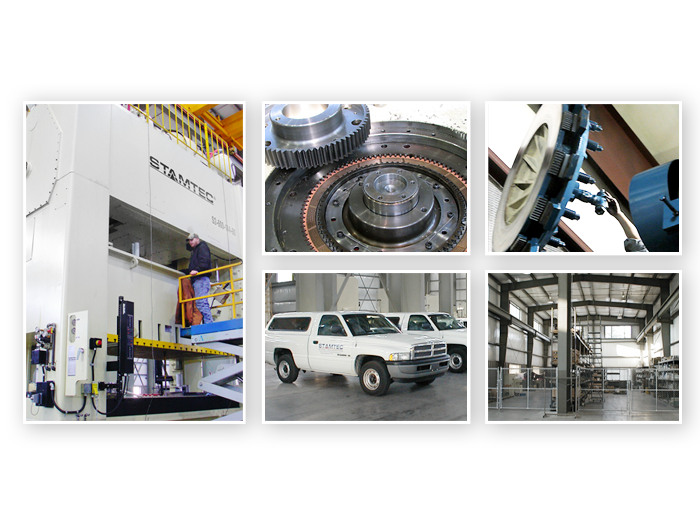

Stamtec, Inc has been providing dependable, affordably priced metal stamping presses for more than 30 years in the North American market, and nearly 70 years worldwide through our parent company Chin Fong.

The repair and rebuild department was formed in order to provide additional services for major repair and rebuild of Stamtec presses. Our knowledgeable staff has years of field-service experience, so whether the project involves a small gap frame press or a large transfer press, or anything in-between, we can meet your repair requirements.

Give us a call at 931-393-5050 to explore how Stamtec can assist you in repairing your press room equipment.

Mechanical and Servo Press Repairs

We will repair your Stamtec equipment on location if at all possible.

All jobs are important to us, whether it is a simple adjustment, minor repair, complete rebuild, or anything between.

We will perform maintenance repair, up keep and partial rebuilds that are more common than the need for a total rebuild. This may include simple adjustments, replacement part, repairing, reconditioning, rebuilding, or even the re-engineering and making of a new part.

Field Service / Inspections

Stamtec Repair / Rebuild Department has highly skilled Field Service Technicians, with years of field experience, who are experts in inspection, maintenance, repair and installation of mechanical presses.

We will supply information regarding the condition of your press to accurately predict wear and premature failure of various systems and components. Combined with a preventive maintenance program, inspection of your press will help eliminate downtime of your equipment and track the progression of wear.

We can tailor an inspection program to fit your needs.

We offer fast efficient service to reduce costly downtime.

Other Stamping Press Services