Photos / Videos / Catalogs

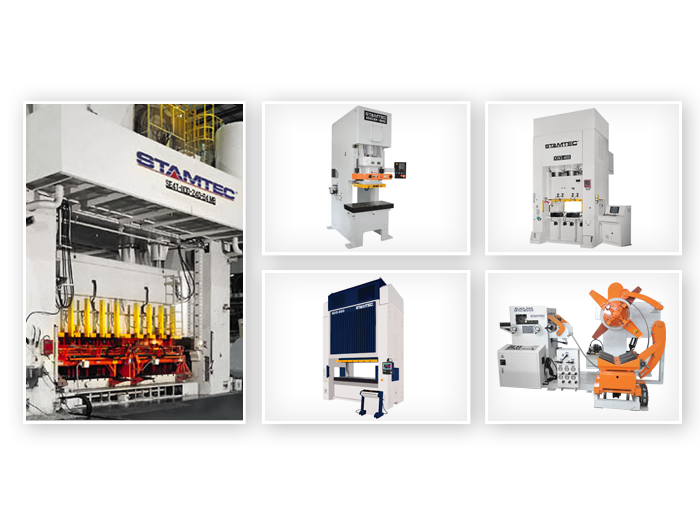

See Stamtec presses' versatility, dependability & durability in action

See Stamtec presses' versatility, dependability & durability in action

Scroll down to view our informative Support Services videos or select a link to see videos on a different topic.

Corporate | Mechanical Presses | Servo Presses | Auxiliary Equipment | Webinars

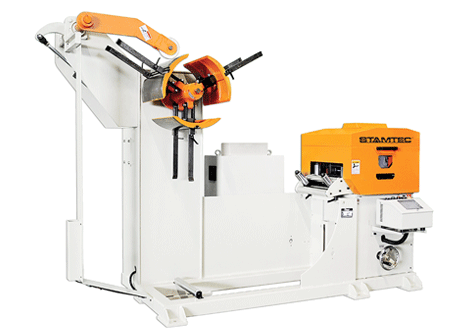

You can also click here for the image gallery and see for yourself the difference a Stamtec machine can make in your metal forming or stamping operation. Or click here for the complete list of our stamping press catalogs.

For the parts or support services you need, please contact us and our representatives would be happy to assist.

Spare & Replacement Parts Inventory

Checking Connecting Rod Ball Cup Clearance

Opening Counterbalance Relief Valve

Checking Ball Cup and Overall Press Clearance

Stamtec Presses’ Hydraulic Overload Protection System

View this presentation in slide show format.

Stamtec OmniLink 5100-MPC Press Control

How to Maintain a Stamtec Stamping Press Counter Balance System

How to Maintain a Stamtec Stamping Press Grease Lubrication System

How to Drain & Fill Wet Clutch Fluid for a Stamtec Stamping Press

View this presentation in slide show format.