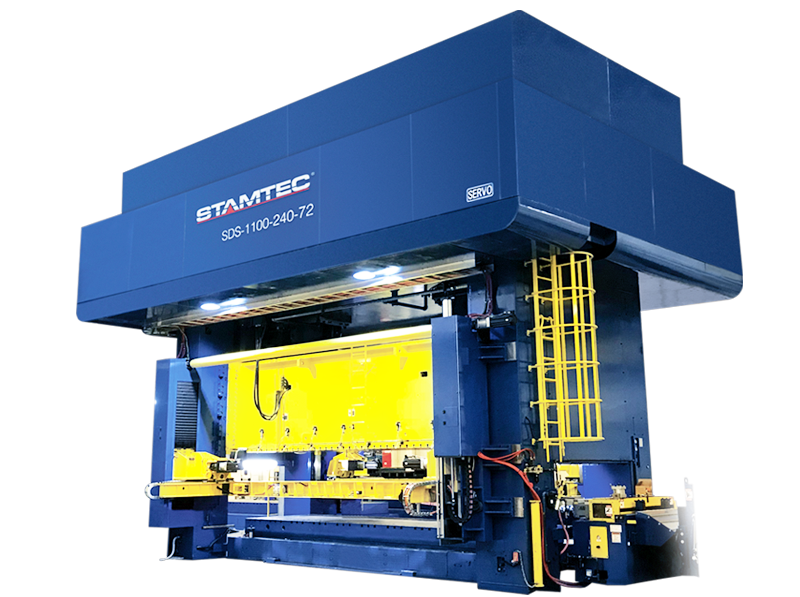

Servo Press

Providing flexibility, productivity & profitability, with a virtually unlimited number of stroke & slide movement profiles

REQUEST A CUSTOM QUOTE

Providing flexibility, productivity & profitability, with a virtually unlimited number of stroke & slide movement profiles

REQUEST A CUSTOM QUOTEIntelligence. Diversification. Eco-Friendly.

Like all Stamtec Servo Presses, the iS1 Series uses the BEST in servo motor technology and controls to enable a virtually unlimited number of stroke and slide movement profiles, while supplying full working energy even at slow speeds / dwells.

What does this mean for your ability to make parts?

TONNAGE RANGE: 176 - 550

Review the specs, advantages and features below and then contact us for help in identifying the servo press that meets your needs.

| MODEL iS2-160 SPECIFICATIONS | ||

|---|---|---|

| Capacity | US Tons | 176 |

| Metric Tons | 160 | |

| Rated tonnage point | in. | 0.24 |

| mm | 6 | |

| Stroke length | in. | 8.66 |

| mm | 220 | |

| Speed | SPM | ~ 60 |

| Die height | in. | 17.72 |

| mm | 450 | |

| Slide adjustment | in. | 3.94 |

| mm | 100 | |

| Slide area (LR x FB) | in. | 64.96 x 23.62 |

| mm | 1650 x 600 | |

| Bolster area | in. | 76.77 x 31.50 |

| mm | 1950 x 800 | |

| Side frame opening (window) (F-B x H) | in. | 31.50 x 15.75 |

| mm | 800 x 400 | |

| Bolster thickness | in. | 6.3 |

| mm | 160 | |

| Maximum upper die weight | lbs. | 2204.62 |

| kgs | 1000 | |

| Slide adjustment motor | kW x P | 0.75 x 6 |

| Working height | in. | 37.4 |

| mm | 950 | |

| Air pressure required | PSI | 71.12 |

| kg / cm2 | 5 | |

| MODEL iS2-200 SPECIFICATIONS | ||

|---|---|---|

| Capacity | US Tons | 220 |

| Metric Tons | 200 | |

| Rated tonnage point | in. | 0.24 |

| mm | 6 | |

| Stroke length | in. | 9.84 |

| mm | 250 | |

| Speed | SPM | ~ 50 |

| Die height | in. | 19.69 |

| mm | 500 | |

| Slide adjustment | in. | 4.33 |

| mm | 110 | |

| Slide area (LR x FB) | in. | 76.77 x 27.56 |

| mm | 1950 x 700 | |

| Bolster area | in. | 88.58 x 35.43 |

| mm | 2250 x 900 | |

| Side frame opening (window) (F-B x H) | in. | 35.43 x 17.72 |

| mm | 900 x 450 | |

| Bolster thickness | in. | 6.69 |

| mm | 170 | |

| Maximum upper die weight | lbs. | 2645.55 |

| kgs | 1200 | |

| Slide adjustment motor | kW x P | 1.5 x 4 |

| Working height | in. | 39.27 |

| mm | 1000 | |

| Air pressure required | PSI | 71.12 |

| kg / cm2 | 5 | |

| MODEL iS2-300 SPECIFICATIONS | ||

|---|---|---|

| Capacity | US Tons | 330 |

| Metric Tons | 300 | |

| Rated tonnage point | in. | 0.24 |

| mm | 6 | |

| Stroke length | in. | 11.81 |

| mm | 300 | |

| Speed | SPM | ~ 40 |

| Die height | in. | 23.62 |

| mm | 600 | |

| Slide adjustment | in. | 4.72 |

| mm | 120 | |

| Slide area (LR x FB) | in. | 90.55 x 33.47 |

| mm | 2300 x 850 | |

| Bolster area | in. | 102.36 x 43.31 |

| mm | 2600 x 1100 | |

| Side frame opening (window) (F-B x H) | in. | 43.31 x 21.65 |

| mm | 1100 x 550 | |

| Bolster thickness | in. | 7.48 |

| mm | 190 | |

| Maximum upper die weight | lbs. | 4409.25 |

| kgs | 2000 | |

| Slide adjustment motor | kW x P | 1.5 x 4 |

| Working height | in. | 45.28 |

| mm | 1150 | |

| Air pressure required | PSI | 71.12 |

| kg / cm2 | 5 | |

| MODEL iS2-400 SPECIFICATIONS | ||

|---|---|---|

| Capacity | US Tons | 440 |

| Metric Tons | 400 | |

| Rated tonnage point | in. | 0.24 |

| mm | 6 | |

| Stroke length | in. | 11.81 |

| mm | 300 | |

| Speed | SPM | ~ 40 |

| Die height | in. | 25.59 |

| mm | 650 | |

| Slide adjustment | in. | 4.72 |

| mm | 120 | |

| Slide area (LR x FB) | in. | 94.49 x 43.31 |

| mm | 2400 x 1100 | |

| Bolster area | in. | 106.30 x 47.24 |

| mm | 2700 x 1200 | |

| Side frame opening (window) (F-B x H) | in. | 47.24 x 23.62 |

| mm | 1200 x 600 | |

| Bolster thickness | in. | 7.48 |

| mm | 190 | |

| Maximum upper die weight | lbs. | 5511.56 |

| kgs | 2500 | |

| Slide adjustment motor | kW x P | 1.5 x 4 |

| Working height | in. | 47.24 |

| mm | 1200 | |

| Air pressure required | PSI | 71.12 |

| kg / cm2 | 5 | |

| MODEL iS2-500 SPECIFICATIONS | ||

|---|---|---|

| Capacity | US Tons | 606 |

| Metric Tons | 500 | |

| Rated tonnage point | in. | 0.24 |

| mm | 6 | |

| Stroke length | in. | 13.78 |

| mm | 350 | |

| Speed | SPM | ~ 40 |

| Die height | in. | 27.56 |

| mm | 700 | |

| Slide adjustment | in. | 4.72 |

| mm | 120 | |

| Slide area (LR x FB) | in. | 94.49 x 43.31 |

| mm | 2400 x 1100 | |

| Bolster area | in. | 106.30 x 51.18 |

| mm | 2700 x 1300 | |

| Side frame opening (window) (F-B x H) | in. | 51.18 x 25.59 |

| mm | 1300 x 650 | |

| Bolster thickness | in. | 7.48 |

| mm | 190 | |

| Maximum upper die weight | lbs. | 6613.87 |

| kgs | 3000 | |

| Slide adjustment motor | kW x P | 1.5 x 4 |

| Working height | in. | 51.18 |

| mm | 1300 | |

| Air pressure required | PSI | 71.12 |

| kg / cm2 | 5 | |

Please contact Stamtec for information concerning components for our iS2 Series metal presses.