Servo Press

Providing flexibility, productivity & profitability, with a virtually unlimited number of stroke & slide movement profiles

REQUEST A CUSTOM QUOTE

Providing flexibility, productivity & profitability, with a virtually unlimited number of stroke & slide movement profiles

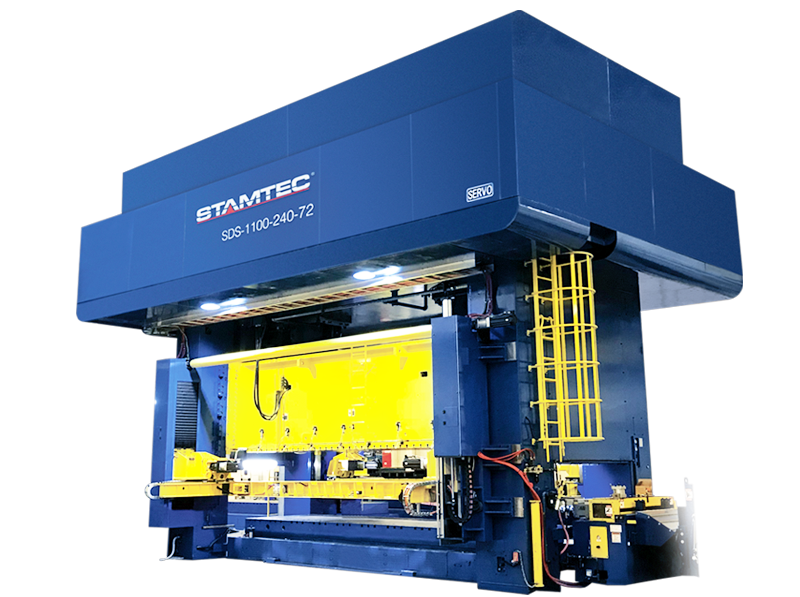

REQUEST A CUSTOM QUOTEWith Stamtec’s servo motor drive technology, the standard electric motor, flywheel and clutch and brake are replaced with a high-torque, low-rpm servo motor. Proprietary press controls specifically designed for the Servo Mechanical Press achieve a wide variety of stroke lengths and slide movement profiles while supplying full working energy even at low speeds.

Stamtec can design a custom Servo Press to your exact needs. From 80 ton C-Frame to 2400 ton Straight-Side, your Servo Mechanical Press solution will help you achieve greater productivity and profitability in today’s competitive stamping market.

Contact Stamtec for a list of IN-STOCK Servo Presses at our BEST PRICING EVER.

Which Servo Press is right for you? Well, it depends. Download our guide to Mechanical vs. Hydraulic vs. Servo Presses to help you decide.

Servo Presses are ideal for applications that require a variable slide velocity at multiple points in the stroke profile, including metal forming and shallow to medium drawing and forming.

A Servo Press is driven by a servo motor, as opposed to a standard flywheel, clutch and brake. This provides full energy at any speed, but not full capacity at any stage in the stroke (capacity is best at near bottom center).

A Servo Press offers increased production volume when compared to a hydraulic press. Also, all stroke profiles are fully programmable on a Servo Press.

Contact Stamtec for a list of IN-STOCK Servo Presses at our BEST PRICING EVER.

With high-torque, low-rpm servo motors and press controls specifically designed for the Servo Press, these machines offer a wide variety of slide movement profiles while maintaining full working energy capacity even at low speeds. Air-cooling keeps the motors and drives performing optimally, while an energy management system eliminates high spikes in direct energy demand from the electrical grid. With Stamtec's Servo Drive Press, you can increase your manufacturing efficiency and precision while reducing energy costs. Don't miss out on this opportunity to revolutionize your manufacturing process.

This gap frame Servo Press features a one-point, fixed-height connection between the slide and the frame, ensuring maximum precision and accuracy in your production process. With its Servo drive press technology, the iS1-200 offers greater control over the press stroke, speed, and force, resulting in increased efficiency and quality. Don't miss out on this opportunity to take your manufacturing process to the next level with Stamtec's iS1-200 Servo Press.