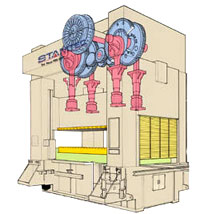

Stamtec’s Mechanical Presses (a.k.a. OBG, OBS, OBI, or C-frame) undergo finite element analysis prior to manufacturing to ensure proper design, superior strength and maximum resistance to deflection

Stamtec's transfer press is designed to run dies with very large dimensions, both left to right and front to back. It can run progressive or transfer dies, running large, odd-shaped or deep-formed parts that require a transfer system to move the parts through the die. Stamtec will work with the transfer system provider of your choice (e.g., AP&T, Atlas, Gudel, HMS, Linear, Nobel, Wayne Trail) to integrate the transfer system completely with the press, feed line and other peripheral equipment as necessary.

The drivetrain is a low-inertia, high-torque, eccentric-geared drive system featuring precision-cut, steel-rim eccentric gears; plunger guiding; and double-helical gearing for the driveshaft and intermediate gears—all lubricated by an enclosed oil bath and spray system. These features maximize control of side thrust and deliver precision slide tracking throughout the stroke. All gear surfaces are heat treated and finely ground to assure smooth operation and low noise levels.

TONNAGE RANGE: 660 - 4,400

DELIVERY TIME: 18-20 weeks

Each Stamtec mechanical press can be customized to meet a wider range of SPM, stroke, rating point (BDC), bed and other specifications and dimensions.

Read the advantages and features below to learn more and then contact us for the right transfer press for your application.

All gears are produced at CF Stamtec’s state-of-the-art manufacturing facilities, using the most modern gear manufacturing equipment and strict quality control procedures. All large gears are balanced for smooth operation. The result is a metal press drive system that provides close running tolerances, prolonged life and smooth, quiet operation.

All gears are produced at CF Stamtec’s state-of-the-art manufacturing facilities, using the most modern gear manufacturing equipment and strict quality control procedures. All large gears are balanced for smooth operation. The result is a metal press drive system that provides close running tolerances, prolonged life and smooth, quiet operation.

This type of drive carries much higher torque loads than crankshaft style drives. In addition, no torsional force is transmitted to the main eccentric gear shafts, which helps to ensure precise slide movement on our transfer presses. The stamping loads are transferred through the gear teeth and the connection straps, so pressure and wear on the bronze alloy bushings is reduced to a minimum.

The four-point straight side press can run extremely large parts, or large dies with many stations, which can eliminate many secondary operations normally performed outside the press. When used as a transfer press, scrap savings of up to 17 percent may be achieved because a scrap skeleton is not necessary to move the parts through the die.

Stamtec will work with the transfer system provider of your choice (e.g., HMS, Wayne Trail, Linear, Noble, Gudel, Atlas), to integrate the transfer system completely with the press, feed line and other peripheral equipment as necessary.

Please contact Stamtec for information on our transfer press components.