Stamtec’s Mechanical Presses (a.k.a. OBG, OBS, OBI, or C-frame) undergo finite element analysis prior to manufacturing to ensure proper design, superior strength and maximum resistance to deflection

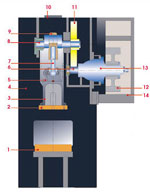

The Stamtec GTX two-point straight side press (a.k.a. double crank press) is designed for stamping relatively long, narrow parts at high single-stroking rates or in continuous mode, using either blanks or coil stock; or running progressive dies that need the longer bed area to accommodate long dies with multiple stations. The GTX double crank press offers an extra-wide, centered, six-point, full-length box gib type. The GTX provides a large die area at a very economical price, while still providing the rigidity and low deflection characteristics of a traditional straight side press.

TONNAGE RANGE: 176 - 550

DELIVERY TIME: some models in stock or with quick delivery

Every Stamtec mechanical stamping press can be customized to meet a wider range of SPM, stroke, rating point (BDC), bed and other specifications and dimensions.

Review the specs, advantages and features below, and then contact us for the double crank press your application requires.

| MODEL GTX-160 SPECIFICATIONS | |||

|---|---|---|---|

| Type | S | H | |

| Capacity | US Tons | 176 | 176 |

| Metric Tons | 160 | 160 | |

| Rated tonnage point | in. | 0.24 | 0.16 |

| mm | 6 | 4 | |

| Stroke length | in. | 7.08 | 5.12 |

| mm | 180 | 130 | |

| Speed | SPM | 30 ~ 55 | 40 ~ 85 |

| Die height | in. | 17.71 | 15.75 |

| mm | 450 | 400 | |

| Maximum upper die weight | lbs. | 2645.55 | 2645.55 |

| Kgs | 1200 | 1200 | |

| Slide adjustment | in. | 3.94 | 3.94 |

| mm | 100 | 100 | |

| Slide area (L-R X F-B) | in. | 63.00 x 25.59 | 63.00 x 25.59 |

| mm | 1600 x 650 | 1600 x 650 | |

| Slide plate thickness | in. | 2.75 | 2.75 |

| mm | 70 | 70 | |

| Bolster area (L-R X F-B) | in. | 71.00 x 29.92 | 71.00 x 29.92 |

| mm | 1800 x 760 | 1800 x 760 | |

| Bolster thickness | in. | 5.91 | 5.91 |

| mm | 150 | 150 | |

| Floor to top of bolster | in. | 39.37 | 39.37 |

| mm | 1000 | 1000 | |

| Side frame opening (window) (F-B x H) | in. | 27.56 x 17.72 | 27.56 x 17.72 |

| mm | 700 x 450 | 700 x 450 | |

| Main motor | Hp x p | 20 x 4 | 20 x 4 |

| Kw x p | 15 x 4 | 15 x 4 | |

| Slide adjusting motor | Hp x p | 1 x 4 | 1 x 4 |

| Kw x p | 0.75 x 4 | 0.75 x 4 | |

| Overall height (approx) | in. | 163.39 | 159.45 |

| mm | 4150 | 4050 | |

| Weight (approx) | lbs. | 59998.81 | 59998.81 |

| kgs | 27215 | 27215 | |

| Parallelism: Slide to bolster - .001" per foot or less | |||

| Deflection: .0015" per foot or less R to L & F to B with 2/3 of the bed symmetrically loaded. | |||

| DIE CUSHION | |||

| Type | S | H | |

| Capacity | US Tons | 8 x 2 | 8 x 2 |

| Metric Tons | 8 x 2 | 8 x 2 | |

| Pad area | in. | 19.69 x 11.81 x 2pcs | 19.69 x 11.81 x 2pcs |

| mm | 500 x 300 x 2pcs | 500 x 300 x 2pcs | |

| Stroke length | in. | 3.15 | 3.15 |

| mm | 80 | 80 | |

| MODEL GTX-200 SPECIFICATIONS | |||

|---|---|---|---|

| Type | S | H | |

| Capacity | US Tons | 220 | 220 |

| Metric Tons | 200 | 200 | |

| Rated tonnage point | in. | 0.24 | 0.16 |

| mm | 6 | 4 | |

| Stroke length | in. | 9.84 | 5.9 |

| mm | 250 | 150 | |

| Speed | SPM | 20 ~ 50 | 35 ~ 70 |

| Die height | in. | 19.68 | 17.72 |

| mm | 500 | 450 | |

| Maxium upper die weight | lbs. | 3306.93 | 3306.93 |

| kgs | 1500 | 1500 | |

| Slide adjustment | in. | 4.72 | 4.72 |

| mm | 120 | 120 | |

| Slide area (L-R X F-B) | in. | 72.83 x 29.53 | 72.83 x 29.53 |

| mm | 1850 x 750 | 1850 x 750 | |

| Slide plate thickness | in. | 3.74 | 3.74 |

| mm | 95 | 95 | |

| Bolster area (L-R X F-B) | in. | 86.61 x 37.00 | 86.61 x 37.00 |

| mm | 2200 x 940 | 2200 x 940 | |

| Bolster thickness | in. | 6.3 | 6.3 |

| mm | 160 | 160 | |

| Floor to top of bolster | in. | 39.37 | 39.37 |

| mm | 1000 | 1000 | |

| Side frame opening (window) (F-B x H) | in. | 35.43 x 23.62 | 35.43 x 23.62 |

| mm | 900 x 600 | 900 x 600 | |

| Main motor | Hp x p | 25 x 4 | 25 x 4 |

| Kw x p | 18.5 x 4 | 18.5 x 4 | |

| Slide adjusting motor | Hp x p | 2 x 4 | 2 x 4 |

| Kw x p | 1.5 x 4 | 1.5 x 4 | |

| Overall height (approx) | in. | 183.07 | 177.16 |

| mm | 4650 | 4500 | |

| Weight (approx) | lbs. | 61729.43 | 61729.43 |

| kgs | 28000 | 28000 | |

| Parallelism: Slide to bolster - .001" per foot or less | |||

| Deflection: .0015" per foot or less R to L & F to B with 2/3 of the bed symmetrically loaded. | |||

| DIE CUSHION | |||

| Type | S | H | |

| Capacity | US Tons | 11 x 2 | 11 x 2 |

| Metric Tons | 10 x 2 | 10 x 2 | |

| Pad area | in. | 21.26 x 13.78 x 2pcs | 21.26 x 13.78 x 2pcs |

| mm | 540 x 350 x 2pcs | 540 x 350 x 2pcs | |

| Stroke length | in. | 4.72 | 4.72 |

| mm | 120 | 80 | |

| MODEL GTX-250 SPECIFICATIONS | |||

|---|---|---|---|

| Type | S | H | |

| Capacity | US Tons | 275 | 275 |

| Metric Tons | 250 | 250 | |

| Rated tonnage point | in. | 0.28 | 0.2 |

| mm | 7 | 5 | |

| Stroke length | in. | 11.02 | 6.69 |

| mm | 280 | 170 | |

| Speed | SPM | 20 ~ 40 | 30 ~ 60 |

| Die height | in. | 21.65 | 17.72 |

| mm | 550 | 450 | |

| Maxium upper die weight | lbs. | 4850.17 | 4850.17 |

| kgs | 2200 | 2200 | |

| Slide adjustment | in. | 4.72 | 4.72 |

| mm | 120 | 120 | |

| Slide area (L-R X F-B) | [A] in. | 86.61 x 35.43 | 86.61 x 35.43 |

| [A] mm | 2200 x 900 | 2200 x 900 | |

| [B] in. | 98.43 x 35.43 | 98.43 x 35.43 | |

| [B] mm | 2500 x 900 | 2500 x 900 | |

| Slide plate thickness | in. | 3.74 | 3.74 |

| mm | 95 | 95 | |

| Bolster area (L-R X F-B) | [A] in. | 98.43 x 39.37 | 98.43 x 39.37 |

| [A] mm | 2500 x 1000 | 2500 x 1000 | |

| [B] in. | 110.24 x 39.37 | 110.24 x 39.37 | |

| [B] mm | 2800 x 1000 | 2800 x 1000 | |

| Bolster thickness | in. | 6.3 | 6.3 |

| mm | 160 | 160 | |

| Floor to top of bolster | in. | 39.37 | 39.37 |

| mm | 1000 | 1000 | |

| Side frame opening (window) (F-B x H) | in. | 35.43 x 23.62 | 35.43 x 23.62 |

| mm | 900 x 600 | 900 x 600 | |

| Main motor | Hp x p | 30 x 4 | 30 x 4 |

| Kw x p | 22 x 4 | 22 x 4 | |

| Slide adjusting motor | Hp x p | 2 x 4 | 2 x 4 |

| Kw x p | 1.5 x 4 | 1.5 x 4 | |

| Overall height (approx) | in. | 194.88 | 194.88 |

| mm | 4950 | 4950 | |

| Weight (approx) | lbs. | 88846 | 88846 |

| kgs | 41000 | 41000 | |

| Parallelism: Slide to bolster - .001" per foot or less | |||

| Deflection: .0015" per foot or less R to L & F to B with 2/3 of the bed symmetrically loaded. | |||

| DIE CUSHION | |||

| Type | S | H | |

| Capacity | US Tons | 15 x 2 | 15 x 2 |

| Metric Tons | 14 x 2 | 14 x 2 | |

| Pad area | in. | 25.20 x 18.50 x 2pcs | 25.20 x 18.50 x 2pcs |

| mm | 640 x 470 x 2pcs | 640 x 470 x 2pcs | |

| Stroke length | in. | 5.51 | 5.51 |

| mm | 140 | 140 | |

| MODEL GTX-300 SPECIFICATIONS | ||||

|---|---|---|---|---|

| Type | S | H | ||

| Capacity | US Tons | 330 | 330 | |

| Metric Tons | 300 | 300 | ||

| Rated tonnage point | in. | 0.28 | 0.2 | |

| mm | 7 | 5 | ||

| Stroke length | in. | 11.81 | 6.69 | |

| mm | 300 | 170 | ||

| Speed | SPM | 20 ~ 40 | 30 ~ 50 | |

| Die height | in. | 21.65 | 17.72 | |

| mm | 550 | 450 | ||

| Maximum upper die weight | [A] lbs. | 5291.1 | 5291.1 | |

| [A] kgs. | 2400 | 2400 | ||

| [B] lbs. | 5291.1 | 5291.1 | ||

| [B] kgs | 2400 | 2400 | ||

| [C] lbs. | 7054.79 | 7054.79 | ||

| [C] kgs. | 3200 | 3200 | ||

| [D] lbs. | 7054.79 | 7054.79 | ||

| [D] kgs | 3200 | 3200 | ||

| Slide adjustment | in. | 4.72 | 4.72 | |

| mm | 120 | 120 | ||

| Slide area (L-R X F-B) | [A] in. | 86.61 x 35.43 | 86.61 x 35.43 | |

| [A] mm | 2200 x 900 | 2200 x 900 | ||

| [B] in. | 98.42 x 35.43 | 98.42 x 35.43 | ||

| [B] mm | 2500 x 900 | 2500 x 900 | ||

| [C] in. | 110.23 x 35.43 | 110.23 x 35.43 | ||

| [C] mm | 2800 x 900 | 2800 x 900 | ||

| [D] in. | 122.04 x 35.43 | 122.04 x 35.43 | ||

| [D] mm | 3100 x 900 | 3100 x 900 | ||

| Slide plate thickness | in. | 3.74 | 3.74 | |

| mm | 95 | 95 | ||

| Bolster area (L-R X F-B) | [A] in. | 98.43 x 39.37 | 98.43 x 39.37 | |

| [A] mm | 2500 x 1000 | 2500 x 1000 | ||

| [B] in. | 110.24 x 39.37 | 110.24 x 39.37 | ||

| [B] mm | 2800 x 1000 | 2800 x 1000 | ||

| [C] in. | 122.05 x 39.37 | 122.05 x 39.37 | ||

| [C] mm | 3100 x 1000 | 3100 x 1000 | ||

| [D] in. | 133.86 x 39.37 | 133.86 x 39.37 | ||

| [D] mm | 3400 x 1000 | 3400 x 1000 | ||

| Bolster thickness | in. | 7.48 | 7.48 | |

| mm | 190 | 190 | ||

| Floor to top of bolster | in. | 47.24 | 47.24 | |

| mm | 1200 | 1200 | ||

| Side frame opening (window) (F-B x H) | in. | 35.43 x 23.62 | 35.43 x 23.62 | |

| mm | 900 x 600 | 900 x 600 | ||

| Main motor | Hp x p | 40 x 4 | 40 x 4 | |

| Kw x p | 30 x 4 | 30 x 4 | ||

| Slide adjusting motor | Hp x p | 2 x 4 | 2 x 4 | |

| Kw x p | 1.5 x 4 | 1.5 x 4 | ||

| Overall height (approx) | in. | 208.66 | 202.76 | |

| mm | 5300 | 5150 | ||

| Weight (approx) | lbs. | 90390 | 90390 | |

| kgs | 40300 | 40300 | ||

| Parallelism: Slide to bolster - .001" per foot or less | ||||

| Deflection: .0015" per foot or less R to L & F to B with 2/3 of the bed symmetrically loaded. | ||||

| DIE CUSHION | ||||

| Type | S | H | ||

| Capacity | US Tons | 15 x 2 | 15 x 2 | |

| Metric Tons | 14 x 2 | 14 x 2 | ||

| Pad area | in. | 25.20 x 18.50 x 2pcs | 25.20 x 18.50 x 2pcs | |

| mm | 640 x 470 x 2pcs | 640 x 470 x 2pcs | ||

| Stroke length | in. | 5.51 | 5.51 | |

| mm | 140 | 140 | ||

| MODEL GTX-400 SPECIFICATIONS | |||

|---|---|---|---|

| Type | S | H | |

| Capacity | US Tons | 440 | 440 |

| Metric Tons | 400 | 400 | |

| Rated tonnage point | in. | 0.28 | 0.24 |

| mm | 7 | 6 | |

| Stroke length | in. | 11.81 | 6.69 |

| mm | 300 | 170 | |

| Speed | SPM | 20 ~ 40 | 30 ~ 50 |

| Die height | in. | 21.65 | 17.72 |

| mm | 550 | 450 | |

| Maximum upper die weight | [A] lbs. | 5291.1 | 5291.1 |

| [A] kgs. | 2400 | 2400 | |

| [B] lbs. | 5291.1 | 5291.1 | |

| [B] kgs | 2400 | 2400 | |

| [C] lbs. | 7054.79 | 7054.79 | |

| [C] kgs. | 3200 | 3200 | |

| [D] lbs. | 7054.79 | 7054.79 | |

| [D] kgs | 3200 | 3200 | |

| Slide adjustment | in. | 4.72 | 4.72 |

| mm | 120 | 120 | |

| Slide area (L-R X F-B) | [A] in. | 86.61 x 35.43 | 86.61 x 35.43 |

| [A] mm | 2200 x 900 | 2200 x 900 | |

| [B] in. | 110.23 x 35.43 | 110.23 x 35.43 | |

| [B] mm | 2500 x 900 | 2500 x 900 | |

| [C] in. | 110.23 x 35.43 | 110.23 x 35.43 | |

| [C] mm | 2800 x 900 | 2800 x 900 | |

| [D] in. | 122.04 x 35.43 | 122.04 x 35.43 | |

| [D] mm | 3100 x 900 | 3100 x 900 | |

| Slide plate thickness | in. | 3.74 | 3.74 |

| mm | 95 | 95 | |

| Bolster area (L-R X F-B) | [A] in. | 98.43 x 39.37 | 98.43 x 39.37 |

| [A] mm | 2500 x 1000 | 2500 x 1000 | |

| [B] in. | 110.24 x 39.37 | 110.24 x 39.37 | |

| [B] mm | 2800 x 1000 | 2800 x 1000 | |

| [C] in. | 122.05 x 39.37 | 122.05 x 39.37 | |

| [C] mm | 3100 x 1000 | 3100 x 1000 | |

| [D] in. | 133.86 x 39.37 | 133.86 x 39.37 | |

| [D] mm | 3400 x 1000 | 3400 x 1000 | |

| Bolster thickness | in. | 7.48 | 7.48 |

| mm | 190 | 190 | |

| Floor to top of bolster | in. | 47.24 | 47.24 |

| mm | 1200 | 1200 | |

| Side frame opening (window) (F-B x H) | in. | 35.43 x 23.62 | 35.43 x 23.62 |

| mm | 900 x 600 | 900 x 600 | |

| Main motor | Hp x p | 50 x 4 | 50 x 4 |

| Kw x p | 37 x 4 | 37 x 4 | |

| Slide adjusting motor | Hp x p | 2 x 4 | 2 x 4 |

| Kw x p | 1.5 x 4 | 1.5 x 4 | |

| Overall height (approx) | in. | 219.69 | 224.41 |

| mm | 5580 | 5700 | |

| Weight (approx) | lbs. | 121254.24 | 121254.24 |

| kgs | 55000 | 55000 | |

| Parallelism: Slide to bolster - .001" per foot or less | |||

| Deflection: .0015" per foot or less R to L & F to B with 2/3 of the bed symmetrically loaded. | |||

| DIE CUSHION | |||

| Type | S | H | |

| Capacity | US Tons | 15 x 2 | 15 x 2 |

| Metric Tons | 14 x 2 | 14 x 2 | |

| Pad area | in. | 25.20 x 18.50 x 2pcs | 25.20 x 18.50 x 2pcs |

| mm | 640 x 470 x 2pcs | 640 x 470 x 2pcs | |

| Stroke length | in. | 5.51 | 5.51 |

| mm | 140 | 140 | |

| MODEL GTX-500 SPECIFICATIONS | |||

|---|---|---|---|

| Type | S | H | |

| Capacity | US Tons | 550 | 550 |

| Metric Tons | 500 | 500 | |

| Rated tonnage point | in. | 0.28 | 0.24 |

| mm | 7 | 6 | |

| Stroke length | in. | 13.78 | 7.87 |

| mm | 350 | 200 | |

| Speed | SPM | 20 ~ 30 | 30 ~ 50 |

| Die height | in. | 21.65 | 19.69 |

| mm | 550 | 500 | |

| Maximum upper die weight | [A] lbs. | 6613.87 | 6613.87 |

| [A] kgs. | 3000 | 3000 | |

| [B] lbs. | 6613.87 | 6613.87 | |

| [B] kgs | 3000 | 3000 | |

| [C] lbs. | 8818.49 | 8818.49 | |

| [C] kgs. | 4000 | 4000 | |

| [D] lbs. | 8818.49 | 8818.49 | |

| [D] kgs | 4000 | 4000 | |

| Slide adjustment | in. | 4.72 | 4.72 |

| mm | 120 | 120 | |

| Slide area (L-R X F-B) | [A] in. | 86.61 x 35.43 | 86.61 x 35.43 |

| [A] mm | 2200 x 900 | 2200 x 900 | |

| [B] in. | 98.43 x 35.43 | 98.43 x 35.43 | |

| [B] mm | 2500 x 900 | 2500 x 900 | |

| [C] in. | 110.24 x 35.43 | 110.24 x 35.43 | |

| [C] mm | 2800 x 900 | 2800 x 900 | |

| [D] in. | 122.05 x 35.43 | 122.05 x 35.43 | |

| [D] mm | 3100 x 900 | 3100 x 900 | |

| Slide plate thickness | in. | 3.74 | 3.74 |

| mm | 95 | 95 | |

| Bolster area (L-R X F-B) | [A] in. | 98.43 x 39.37 | 98.43 x 39.37 |

| [A] mm | 2500 x 1000 | 2500 x 1000 | |

| [B] in. | 110.24 x 39.37 | 110.24 x 39.37 | |

| [B] mm | 2800 x 1000 | 2800 x 1000 | |

| [C] in. | 122.05 x 39.37 | 122.05 x 39.37 | |

| [C] mm | 3100 x 1000 | 3100 x 1000 | |

| [D] in. | 133.86 x 39.37 | 133.86 x 39.37 | |

| [D] mm | 3400 x 1000 | 3400 x 1000 | |

| Bolster thickness | in. | 9.84 | 9.84 |

| mm | 250 | 250 | |

| Floor to top of bolster | in. | 52.76 | 52.76 |

| mm | 1340 | 1340 | |

| Side frame opening (window) (F-B x H) | in. | 35.43 x 17.72 | 35.43 x 17.72 |

| mm | 900 x 450 | 900 x 450 | |

| Main motor | Hp x p | 60 x 4 | 60 x 4 |

| Kw x p | 45 x 4 | 45 x 4 | |

| Slide adjusting motor | Hp x p | 3 x 4 | 3 x 4 |

| Kw x p | 2.2 x 4 | 2.2 x 4 | |

| Overall height (approx) | in. | 230.9 | 230.9 |

| mm | 5865 | 5865 | |

| Weight (approx) | lbs. | 121254.24 | 121254.24 |

| kgs | 55000 | 55000 | |

| Parallelism: Slide to bolster - .001" per foot or less | |||

| Deflection: .0015" per foot or less R to L & F to B with 2/3 of the bed symmetrically loaded. | |||

| DIE CUSHION | |||

| Type | S | H | |

| Capacity | US Tons | 15 x 2 | 15 x 2 |

| Metric Tons | 14 x 2 | 14 x 2 | |

| Pad area | in. | 25.20 x 18.50 x 2pcs | 25.20 x 18.50 x 2pcs |

| mm | 640 x 470 x 2pcs | 640 x 470 x 2pcs | |

| Stroke length | in. | 5.51 | 5.51 |

| mm | 140 | 140 | |