Stamtec’s Mechanical Presses (a.k.a. OBG, OBS, OBI, or C-frame) undergo finite element analysis prior to manufacturing to ensure proper design, superior strength and maximum resistance to deflection

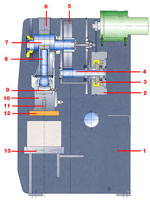

The Stamtec SC1 straight side press (a.k.a. single crank press) is designed for stamping small parts at high single-stroking rates or in continuous mode, using either blanks or coil stock. Economically priced when compared to a gap frame press, the SC1 offers similar angular deflection characteristics. The design of the SC1 mechanical press also allows for easy adaptation of automation equipment.

TONNAGE RANGE: 88-276

DELIVERY TIME: 20-22 weeks

View the press features and advantages below, and then contact us by calling 931-393-5050 or submitting this online form for more information on our S1 Series Straight Side Press.

Every Stamtec mechanical press can be customized to meet a wider range of SPM, stroke, rating point (BDC), bed and other specifications and dimensions.

| MODEL SC1-80 SPECIFICATIONS | ||||

|---|---|---|---|---|

| Type | S | H | L | |

| Capacity | US Tons | 88 | 88 | 88 |

| Metric Tons | 80 | 80 | 80 | |

| Rated tonnage point | in. | 0.2 | 0.13 | 0.2 |

| mm | 5 | 3.2 | 5 | |

| Stroke length | in. | 3.94 | 2.36 | 6.3 |

| mm | 100 | 60 | 160 | |

| Strokes per minute | Variable | - | - | 60 |

| Fixed | 55 ~ 110 | 75 ~ 150 | 40 ~ 75 | |

| Die height | in. | 11.81 | 11.81 | 12.99 |

| mm | 300 | 300 | 330 | |

| Maximum upper die weight | lbs. | 881.85 | 881.85 | 881.85 |

| Kgs | 400 | 400 | 400 | |

| Slide adjustment | in. | 3.15 | 3.15 | 3.15 |

| mm | 80 | 80 | 80 | |

| Bolster area (L-R x F-B) | in. | 29.53 x 18.11 | 29.53 x 18.11 | 29.53 x 23.62 |

| mm | 750 x 460 | 750 x 460 | 750 x 600 | |

| Slide area (L-R x F-B) | in. | 22.05 x 18.11 | 22.05 x 18.11 | 22.05 x 18.11 |

| mm | 560 x 460 | 560 x 460 | 560 x 460 | |

| Slide opening (F-B x H) | in. | 20.08 x 16.93 | 20.08 x 16.93 | 25.59 x 18.11 |

| mm | 510 x 430 | 510 x 430 | 650 x 460 | |

| Scrap area (L-R x H) | in. | 18.90 x 11.02 | 18.90 x 11.02 | 18.90 x 11.02 |

| mm | 480 x 280 | 480 x 280 | 480 x 280 | |

| Main motor | Kw x p | 5.5 x 4 | 5.5 x 4 | 5.5 x 4 |

| Hp x p | 7.5 x 4 | 7.5 x 4 | 7.5 x 4 | |

| Slide adjusting motor | Kw x p | 0.4 x 4 | 0.4 x 4 | 0.4 x 4 |

| Hp x p | 0.5 x 4 | 0.5 x 4 | 0.5 x 4 | |

| DIE CUSHION | ||||

| Type | S | H | L | |

| Capacity | US Tons | - | - | 6 |

| Metric Tons | - | - | 6.3 | |

| Pad area (LR x FB) | in. | 16.14 x 10.24 | 16.14 x 10.24 | 16.14 x 10.24 |

| mm | 410 x 260 | 410 x 260 | 410 x 260 | |

| Stroke | in. | 2.76 | 2.76 | 2.76 |

| mm | 70 | 70 | 70 | |

| MACHINE DIMENSIONS | ||||

| Type | S | H | L | |

| Width (LR) | in. | 48.43 | 48.43 | 48.43 |

| mm | 1230 | 1230 | 1230 | |

| Depth (FB) | in. | 68.11 | 68.11 | 70.87 |

| mm | 1730 | 1730 | 1800 | |

| Height (H) | in. | 111.02 | 111.02 | 113.39 |

| mm | 2820 | 2820 | 2880 | |

| MODEL SC1-110 SPECIFICATIONS | |||||

|---|---|---|---|---|---|

| Type | S | H | L | ||

| Capacity | US Tons | 121 | 121 | 121 | |

| Metric Tons | 110 | 110 | 110 | ||

| Rated tonnage point | in. | 0.2 | 0.13 | 0.2 | |

| mm | 5 | 3.2 | 5 | ||

| Stroke length | in. | 4.33 | 2.76 | 7.09 | |

| mm | 110 | 70 | 180 | ||

| Strokes per minute | Variable | - | - | 50 | |

| Fixed | 50 ~ 100 | 65 ~ 135 | 30 ~ 65 | ||

| Die height | in. | 12.6 | 12.6 | 13.78 | |

| mm | 320 | 320 | 350 | ||

| Maximum upper die weight | lbs. | 992.08 | 992.08 | 992.08 | |

| Kgs | 450 | 450 | 450 | ||

| Slide adjustment | in. | 3.54 | 3.54 | 3.54 | |

| mm | 90 | 90 | 90 | ||

| Bolster area (L-R x F-B) | in. | 35.43 x 20.47 | 35.43 x 20.47 | 35.43 x 27.56 | |

| mm | 900 x 520 | 900 x 520 | 900 x 700 | ||

| Slide area (L-R x F-B) | in. | 25.59 x 20.47 | 25.59 x 20.47 | 25.59 x 20.47 | |

| mm | 650 x 520 | 650 x 520 | 650 x 520 | ||

| Slide opening (F-B x H) | in. | 22.44 x 18.50 | 22.44 x 18.50 | 29.53 x 19.69 | |

| mm | 570 x 470 | 570 x 470 | 750 x 500 | ||

| Scrap area (L-R x H) | in. | 21.26 x 11.02 | 21.26 x 11.02 | 21.26 x 11.02 | |

| mm | 540 x 280 | 540 x 280 | 540 x 280 | ||

| Main motor | Kw x p | 7.5 x 4 | 7.5 x 4 | 7.5 x 4 | |

| Hp x p | 10 x 4 | 10 x 4 | 10 x 4 | ||

| Slide adjusting motor | Kw x p | 0.4 x 4 | 0.4 x 4 | 0.4 x 4 | |

| Hp x p | 0.5 x 4 | 0.5 x 4 | 0.5 x 4 | ||

| DIE CUSHION | |||||

| Type | S | H | L | ||

| Capacity | US Tons | - | - | 8 | |

| Metric Tons | - | - | 8 | ||

| Pad area (LR x FB) | in. | 19.69 x 11.81 | 19.69 x 11.81 | 19.69 x 11.81 | |

| mm | 500 x 300 | 500 x 300 | 500 x 300 | ||

| Stroke | in. | 3.15 | 3.15 | 3.15 | |

| mm | 80 | 80 | 80 | ||

| MACHINE DIMENSIONS | |||||

| Type | S | H | L | ||

| Width (LR) | in. | 53.74 | 53.74 | 53.74 | |

| mm | 1365 | 1365 | 1365 | ||

| Depth (FB) | in. | 76.77 | 76.77 | 80.32 | |

| mm | 1950 | 1950 | 2040 | ||

| Height (H) | in. | 117.32 | 117.32 | 119.88 | |

| mm | 2980 | 2980 | 3045 | ||

| MODEL SC1-160 SPECIFICATIONS | |||||

|---|---|---|---|---|---|

| Type | S | H | L | XL | |

| Capacity | US Tons | 176 | 176 | 176 | 176 |

| Metric Tons | 160 | 160 | 160 | 160 | |

| Rated tonnage point | in. | 0.24 | 0.16 | 0.24 | 0.24 |

| mm | 6 | 4 | 6 | 6 | |

| Stroke length | in. | 5.12 | 3.15 | 7.87 | 9.84 |

| mm | 130 | 80 | 200 | 250 | |

| Strokes per minute | Variable | - | - | 45 | 45 |

| Fixed | 40 ~ 85 | 55 ~ 115 | 25 ~ 50 | 20 ~ 45 | |

| Die height | in. | 13.78 | 13.78 | 17.72 | 17.72 |

| mm | 350 | 350 | 450 | 450 | |

| Maximum upper die weight | lbs. | 1543 | 1543 | 1543 | 1543 |

| Kgs | 700 | 700 | 700 | 700 | |

| Slide adjustment | in. | 3.94 | 3.94 | 3.94 | 3.94 |

| mm | 100 | 100 | 100 | 100 | |

| Bolster area (L-R X F-B) | in. | 39.37 x 22.83 | 39.37 x 22.83 | 39.37 x 29.53 | 39.37 x 29.53 |

| mm | 1000 x 580 | 1000 x 580 | 1000 x 750 | 1000 x 750 | |

| Slide area (L-R X F-B) | in. | 27.56 x 22.83 | 27.56 x 22.83 | 27.56 x 22.83 | 27.56 x 22.83 |

| mm | 700 x 580 | 700 x 580 | 700 x 580 | 700 x 580 | |

| Side opening (F-B x H) | in. | 24.80 x 20.07 | 24.80 x 20.07 | 31.50 x 22.05 | 31.50 x 24.02 |

| mm | 630 x 510 | 630 x 510 | 800 x 560 | 800 x 610 | |

| Scrap opening (F-B x H) | in. | 22.84 x 11.02 | 22.84 x 11.02 | 22.84 x 11.02 | 22.84 x 11.02 |

| mm | 580 x 280 | 580 x 280 | 580 x 280 | 580 x 280 | |

| Main motor | Kw x p | 11 x 4 | 11 x 4 | 11 x 4 | 11 x 4 |

| Hp x p | 15 x 4 | 15 x 4 | 15 x 4 | 15 x 4 | |

| Slide adjusting motor | Kw x p | 0.5 x 4 | 0.5 x 4 | 0.5 x 4 | 0.5 x 4 |

| Hp x p | 0.75 x 4 | 0.75 x 4 | 0.75 x 4 | 0.75 x 4 | |

| DIE CUSHION | |||||

| Type | S | H | L | XL | |

| Capacity | US Tons | - | - | 11 | 11 |

| Metric Tons | - | - | 10 | 10 | |

| Pad area (LR x FB) | in. | 21.26 x 13.78 | 21.26 x 13.78 | 21.26 x 13.78 | 21.26 x 13.78 |

| mm | 540 x 350 | 540 x 350 | 540 x 350 | 540 x 350 | |

| Stroke | in. | 3.15 | 3.15 | 3.15 | 3.15 |

| mm | 80 | 80 | 80 | 80 | |

| MACHINE DIMENSIONS | |||||

| Type | S | H | L | XL | |

| Width (LR) | in. | 59.06 | 59.06 | 59.06 | 59.06 |

| mm | 1500 | 1500 | 1500 | 1500 | |

| Depth (FB) | in. | 86.81 | 86.81 | 90.16 | 90.16 |

| mm | 2205 | 2205 | 2290 | 2290 | |

| Height (H) | in. | 134.25 | 134.25 | 140.35 | 146.06 |

| mm | 3410 | 3410 | 3565 | 3710 | |

| MODEL SC1-200 SPECIFICATIONS | |||||

|---|---|---|---|---|---|

| Type | S | H | L | XL | |

| Capacity | US Tons | 220 | 220 | 220 | 220 |

| Metric Tons | 200 | 200 | 200 | 200 | |

| Rated tonnage point | in. | 0.24 | 0.16 | 0.24 | 0.24 |

| mm | 6 | 4 | 6 | 6 | |

| Stroke length | in. | 5.91 | 3.74 | 7.87 | 9.85 |

| mm | 150 | 95 | 200 | 250 | |

| Strokes per minute | Variable | - | - | 35 | 35 |

| Fixed | 35 ~ 70 | 45 ~ 95 | 20 ~ 45 | 20 ~ 40 | |

| Die height | in. | 16.14 | 16.14 | 17.72 | 17.72 |

| mm | 410 | 410 | 450 | 450 | |

| Maximum upper die weight | lbs. | 31.5 | 31.5 | 31.5 | 31.5 |

| Kgs | 800 | 800 | 800 | 800 | |

| Slide adjustment | in. | 4.33 | 4.33 | 4.33 | 4.33 |

| mm | 110 | 110 | 110 | 110 | |

| Bolster area (L-R X F-B) | in. | 45.28 x 25.59 | 45.28 x 25.59 | 45.28 x 33.47 | 45.28 x 33.47 |

| mm | 1150 x 650 | 1150 x 650 | 1150 x 850 | 1150 x 850 | |

| Slide area (L-R X F-B) | in. | 33.47 x 25.59 | 33.47 x 25.59 | 33.47 x 25.59 | 33.47 x 25.59 |

| mm | 850 x 650 | 850 x 650 | 850 x 650 | 850 x 650 | |

| Side opening (F-B x H) | in. | 27.56 x 22.44 | 27.56 x 22.44 | 35.43 x 24.02 | 35.43 x 24.02 |

| mm | 700 x 570 | 700 x 570 | 900 x 610 | 900 x 610 | |

| Scrap opening (F-B x H) | in. | 27.56 x 11.02 | 27.56 x 11.02 | 27.56 x 11.02 | 27.56 x 11.02 |

| mm | 700 x 280 | 700 x 280 | 700 x 280 | 700 x 280 | |

| Main motor | Kw x p | 15 x 4 | 15 x 4 | 15 x 4 | 15 x 4 |

| Hp x p | 20 x 4 | 20 x 4 | 20 x 4 | 20 x 4 | |

| Slide adjusting motor | Kw x p | 0.75 x 4 | 0.75 x 4 | 0.75 x 4 | 0.75 x 4 |

| Hp x p | 1 x 4 | 1 x 4 | 1 x 4 | 1 x 4 | |

| DIE CUSHION | |||||

| Type | S | H | L | XL | |

| Capacity | US Tons | - | - | 15 | 15 |

| Metric Tons | - | - | 14 | 14 | |

| Pad area (LR x FB) | in. | 25.20 x 18.50 | 25.20 x 18.50 | 25.20 x 18.50 | 25.20 x 18.50 |

| mm | 640 x 470 | 640 x 470 | 640 x 470 | 640 x 470 | |

| Stroke | in. | 3.94 | 3.94 | 3.94 | 3.94 |

| mm | 100 | 100 | 100 | 100 | |

| MACHINE DIMENSIONS | |||||

| Type | S | H | L | XL | |

| Width (LR) | in. | 69.29 | 69.29 | 69.29 | 69.29 |

| mm | 1760 | 1760 | 1760 | 1760 | |

| Depth (FB) | in. | 98.03 | 98.03 | 101.97 | 101.97 |

| mm | 2490 | 2490 | 2590 | 2590 | |

| Height (H) | in. | 149.61 | 149.61 | 152.17 | 157.87 |

| mm | 3800 | 3800 | 3865 | 4010 | |

| MODEL SC1-260 SPECIFICATIONS | |||||

|---|---|---|---|---|---|

| Type | S | H | L | XL | |

| Capacity | US Tons | 286 | 286 | 286 | 286 |

| Metric Tons | 260 | 260 | 260 | 260 | |

| Rated tonnage point | in. | 0.26 | 0.16 | 0.26 | 0.26 |

| mm | 6.5 | 4 | 6.5 | 6.5 | |

| Stroke length | in. | 7.1 | 3.94 | 9.84 | 11.81 |

| mm | 180 | 100 | 250 | 300 | |

| Strokes per minute | Variable | - | - | 30 | 30 |

| Fixed | 30 ~ 60 | 40 ~ 75 | 20 ~ 40 | 20 ~ 35 | |

| Die height | in. | 18.11 | 18.11 | 19.69 | 21.26 |

| mm | 460 | 460 | 500 | 540 | |

| Maximum upper die weight | lbs. | 1763.7 | 1763.7 | 1763.7 | 1763.7 |

| Kgs | 800 | 800 | 800 | 800 | |

| Slide adjustment | in. | 4.72 | 4.72 | 4.72 | 4.72 |

| mm | 120 | 120 | 120 | 120 | |

| Bolster area (L-R X F-B) | in. | 51.18 x 27.56 | 51.18 x 27.56 | 51.18 x 35.43 | 51.18 x 35.43 |

| mm | 1300 x 700 | 1300 x 700 | 1300 x 900 | 1300 x 900 | |

| Slide area (L-R X F-B) | in. | 36.22 x 27.56 | 36.22 x 27.56 | 36.22 x 27.56 | 36.22 x 27.56 |

| mm | 920 x 700 | 920 x 700 | 920 x 700 | 920 x 700 | |

| Side opening (F-B x H) | in. | 29.53 x 24.41 | 29.53 x 24.41 | 29.53 x 24.41 | 29.53 x 24.41 |

| mm | 750 x 620 | 750 x 620 | 950 x 660 | 950 x 700 | |

| Scrap opening (F-B x H) | in. | 27.95 x 11.02 | 27.95 x 11.02 | 27.95 x 11.02 | 27.95 x 11.02 |

| mm | 710 x 280 | 710 x 280 | 710 x 280 | 710 x 280 | |

| Main motor | Kw x p | 19 x 4 | 19 x 4 | 19 x 4 | 19 x 4 |

| Hp x p | 25 x 4 | 25 x 4 | 25 x 4 | 25 x 4 | |

| Slide adjusting motor | Kw x p | 1.5 x 4 | 1.5 x 4 | 1.5 x 4 | 1.5 x 4 |

| Hp x p | 2 x 4 | 2 x 4 | 2 x 4 | 2 x 4 | |

| DIE CUSHION | |||||

| Type | S | H | L | XL | |

| Capacity | US Tons | - | - | 15 | 15 |

| Metric Tons | - | - | 14 | 14 | |

| Pad area (LR x FB) | in. | 27.56 x 18.50 | 27.56 x 18.50 | 27.56 x 18.50 | 27.56 x 18.50 |

| mm | 700 x 470 | 700 x 470 | 700 x 470 | 700 x 470 | |

| Stroke | in. | 3.94 | 3.94 | 3.94 | 3.94 |

| mm | 100 | 100 | 100 | 100 | |

| MACHINE DIMENSIONS | |||||

| Type | S | H | L | XL | |

| Width (LR) | in. | 75.2 | 75.2 | 75.2 | 75.2 |

| mm | 1910 | 1910 | 1910 | 1910 | |

| Depth (FB) | in. | 104.53 | 104.53 | 108.47 | 108.47 |

| mm | 2655 | 2655 | 2755 | 2755 | |

| Height (H) | in. | 166.93 | 166.93 | 170.28 | 176.77 |

| mm | 4240 | 4240 | 4325 | 4490 | |

| MODEL SC1-300 SPECIFICATIONS | ||

|---|---|---|

| Type | XL | |

| Capacity | US Tons | 330 |

| Metric Tons | 300 | |

| Rated tonnage point | in. | 0.28 |

| mm | 7 | |

| Stroke length | in. | 11.81 |

| mm | 300 | |

| Strokes per minute | Variable | 30 |

| Fixed | 20 ~ 35 | |

| Die height | in. | 21.65 |

| mm | 550 | |

| Maximum upper die weight | lbs. | 1984.16 |

| Kgs | 900 | |

| Slide adjustment | in. | 4.72 |

| mm | 120 | |

| Bolster area (L-R X F-B) | in. | 62.99 x 39.37 |

| mm | 1600 x 1000 | |

| Slide area (L-R X F-B) | in. | 55.12 x 35.43 |

| mm | 1400 x 900 | |

| Side opening (F-B x H) | in. | 43.31 x 29.53 |

| mm | 1100 x 750 | |

| Scrap opening (F-B x H) | in. | 39.37 x 16.14 |

| mm | 1000 x 410 | |

| Main motor | Kw x p | 22.5 x 4 |

| Hp x p | 30 x 4 | |

| Slide adjusting motor | Kw x p | 2.2 x 4 |

| Hp x p | 3 x 4 | |

| DIE CUSHION | ||

| Type | XL | |

| Capacity | US Tons | 15 |

| Metric Tons | 14 | |

| Pad area (LR x FB) | in. | 27.56 x 18.50 |

| mm | 700 x 470 | |

| Stroke | in. | 3.94 |

| mm | 100 | |

| MACHINE DIMENSIONS | ||

| Type | XL | |

| Width (LR) | in. | 88.98 |

| mm | 2260 | |

| Depth (FB) | in. | 115.95 |

| mm | 2945 | |

| Height (H) | in. | 178.15 |

| mm | 4525 | |

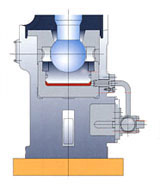

The heavy, stress-relieved and unitized steel frame of these steel stamping machines supplies a solid base to resist deflection and provide accurate stampings and longer die life.

The heavy, stress-relieved and unitized steel frame of these steel stamping machines supplies a solid base to resist deflection and provide accurate stampings and longer die life.

More accurate stampings can be made thanks to the press's lower angular deflection, as compared to a gap press.

Fast-response hydraulic overload relieves the pressure of a tonnage overload in milliseconds, stopping the press immediately and protecting press and dies from damage.

Link motion drive technology

Press controls from industry leaders like Wintriss, Link, Helm (Allen-Bradley), Toledo (Allen-Bradley), Siemens, Mitsubishi, etc.

Anti-vibration press leveling mounts

Safety light curtains

Tonnage monitor

Quick die-change system

Die cushion

Compact servo feed line