Mechanical Forging Press

For many components, cold or hot forging offers crucial production efficiencies & benefits like strength, integrity & material savings.

REQUEST A CUSTOM QUOTE

For many components, cold or hot forging offers crucial production efficiencies & benefits like strength, integrity & material savings.

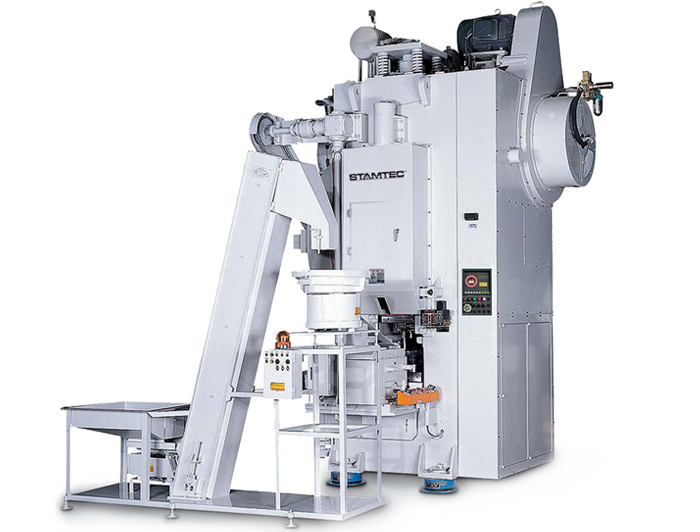

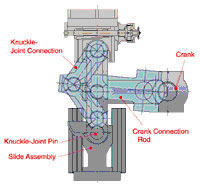

REQUEST A CUSTOM QUOTEStamtec KW2 Series - High Precision Progressive Knuckle-Joint Presses are specially designed for cold forging and are ideal for near net-shape forming. The cold forge technology creates a product with more consistent and durable strength because the process does not cut metal fibers.

» High rigidity - minimum deflection

» Knuckle-joint mechanism longer BDC dwelling time, high precision

» Designed for thicker materials NET-shape blanking and coining

» Improved precision of products

» Prolong tooling life

» Improve quality and stability of high precision products

» Capable for wider stamping applications

» Reduce noise and vibration, improve quality of working environment.

TONNAGE RANGE: 260 - up to 4,000

Review the specs and advantages below and then contact us for more information on the cold forging machine you need.

| MODEL KW2-260 SPECIFICATIONS | ||

|---|---|---|

| Capacity | US Tons | 286 |

| Metric Tons | 260 | |

| Rated tonnage point | in. | 0.32 |

| mm | 8 | |

| Stroke length | in. | 4.72 |

| mm | 120 | |

| Speed | SPM | 35 ~ 50 |

| Die height (S.D.A.U.) | in. | 17.72 |

| mm | 450 | |

| Slide adjustment | in. | 1.97 |

| mm | 50 | |

| Slide area (L.R. x F.B.) | in. | 51.18 x 29.53 |

| mm | 1300 x 750 | |

| Bolster area (L.R. x F.B.) | in. | 51.18 x 29.53 |

| mm | 1300 x 750 | |

| Side frame opening (window) (F-B x H) | in. | 15.75 x 15.75 |

| mm | 400 x 400 | |

| Main motor | Hp x p | 40 x 4 |

| Slide adjusting motor | Kw x p | 1.5 x 4 |

| Working height | in. | 47.0866 |

| mm | 1196 | |

| MODEL KW2-400 SPECIFICATIONS | ||

|---|---|---|

| Capacity | US Tons | 440 |

| Metric Tons | 400 | |

| Rated tonnage point | in. | 0.32 |

| mm | 8 | |

| Stroke length | in. | 6.3 |

| mm | 160 | |

| Speed | SPM | 25 ~ 50 |

| Die height (S.D.A.U.) | in. | 17.72 |

| mm | 450 | |

| Slide adjustment | in. | 2.95 |

| mm | 75 | |

| Slide area (L.R. x F.B.) | in. | 62.99 x 35.43 |

| mm | 1600 x 900 | |

| Bolster area (L.R. x F.B.) | in. | 62.99 x 35.43 |

| mm | 1600 x 900 | |

| Side frame opening (window) (F-B x H) | in. | 31.50 x 23.622 |

| mm | 800 x 600 | |

| Main motor | Hp x p | 75 x 4 |

| Slide adjusting motor | Kw x p | 3.7 x 4 |

| Working height | in. | 44.69 |

| mm | 1135 | |

| MODEL KW2-600 SPECIFICATIONS | ||

|---|---|---|

| Capacity | US Tons | 661 |

| Metric Tons | 600 | |

| Rated tonnage point | in. | 0.32 |

| mm | 8 | |

| Stroke length | in. | 7.87 |

| mm | 200 | |

| Speed | SPM | 25 ~ 45 |

| Die height (S.D.A.U.) | in. | 23.62 |

| mm | 600 | |

| Slide adjustment | in. | 3.94 |

| mm | 100 | |

| Slide area (L.R. x F.B.) | in. | 84.65 x 49.21 |

| mm | 2150 x 1250 | |

| Bolster area (L.R. x F.B.) | in. | 84.65 x 49.21 |

| mm | 2150 x 1250 | |

| Side frame opening (window) (F-B x H) | in. | 51.18 x 34.45 |

| mm | 1300 x 875 | |

| Main motor | Hp x p | 125 x 4 |

| Slide adjusting motor | Kw x p | 3.7 x 6 |

| Working height | in. | 33.47 |

| mm | 850 | |

| MODEL KW2-800 SPECIFICATIONS | ||

|---|---|---|

| Capacity | US Tons | 881 |

| Metric Tons | 800 | |

| Rated tonnage point | in. | 0.32 |

| mm | 8 | |

| Stroke length | in. | 7.87 |

| mm | 200 | |

| Speed | SPM | 25 ~ 40 |

| Die height (S.D.A.U.) | in. | 25.59 |

| mm | 650 | |

| Slide adjustment | in. | 4.72 |

| mm | 120 | |

| Slide area (L.R. x F.B.) | in. | 88.58 x 51.18 |

| mm | 2250 x 1300 | |

| Bolster area (L.R. x F.B.) | in. | 88.58 x 51.18 |

| mm | 2250 x 1300 | |

| Side frame opening (window) (F-B x H) | in. | 55.12 x 34.45 |

| mm | 1400 x 875 | |

| Main motor | Hp x p | 175 x 4 |

| Slide adjusting motor | Kw x p | 7.5 x 6 |

| Working height | in. | 33.47 |

| mm | 850 | |

| MODEL KW2-1000 SPECIFICATIONS | ||

|---|---|---|

| Capacity | US Tons | 1102 |

| Metric Tons | 1000 | |

| Rated tonnage point | in. | 0.32 |

| mm | 8 | |

| Stroke length | in. | 9.84 |

| mm | 250 | |

| Speed | SPM | 20 ~ 35 |

| Die height (S.D.A.U.) | in. | 25.59 |

| mm | 650 | |

| Slide adjustment | in. | 4.72 |

| mm | 120 | |

| Slide area (L.R. x F.B.) | in. | 98.43 x 55.12 |

| mm | 2500 x 1400 | |

| Bolster area (L.R. x F.B.) | in. | 98.43 x 55.12 |

| mm | 2500 x 1400 | |

| Side frame opening (window) (F-B x H) | in. | 57.09 x 34.45 |

| mm | 1450 x 875 | |

| Main motor | Hp x p | 175 x 4 |

| Slide adjusting motor | Kw x p | 7.5 x 6 |

| Working height | in. | 33.47 |

| mm | 850 | |

| MODEL KW2-1200 SPECIFICATIONS | ||

|---|---|---|

| Capacity | US Tons | 1322 |

| Metric Tons | 1200 | |

| Rated tonnage point | in. | 0.32 |

| mm | 8 | |

| Stroke length | in. | 9.84 |

| mm | 250 | |

| Speed | SPM | 20 ~ 35 |

| Die height (S.D.A.U.) | in. | 25.59 |

| mm | 650 | |

| Slide adjustment | in. | 5.91 |

| mm | 150 | |

| Slide area (L.R. x F.B.) | in. | 98.43 x 55.12 |

| mm | 2500 x 1400 | |

| Bolster area (L.R. x F.B.) | in. | 98.43 x 55.12 |

| mm | 2500 x 1400 | |

| Side frame opening (window) (F-B x H) | in. | 57.09 x 34.45 |

| mm | 1450 x 875 | |

| Main motor | Hp x p | 200 x 4 |

| Slide adjusting motor | Kw x p | 7.5 x 6 |

| Working height | in. | 33.47 |

| mm | 850 | |

Specifications available on request.

Give us a call at 931-393-5050 or complete our request form.

Designed for the “net-shape” blanking and coining of thicker materials.

Designed for the “net-shape” blanking and coining of thicker materials.

The system features a low inertia design with the gears running in an oil bath and spray system. For superior strength, durability, accuracy, and consistency, gears are manufactured in our own facilities to the highest manufacturing standards, using high quality steels. The gear teeth are finished ground and hardened to provide close running tolerances, prolonged life, and a smooth quiet operation. The crankshaft is forged from high-carbon steel; precision machined, and the bearings surfaces are smooth ground. The crankshaft main bearings and pitman bushings are custom machined from bronze alloy.